Best Price on Sheet Metal Stamping Parts - Member Body Mounting 2ND RH – Meiln

Best Price on Sheet Metal Stamping Parts - Member Body Mounting 2ND RH – Meiln Detail:

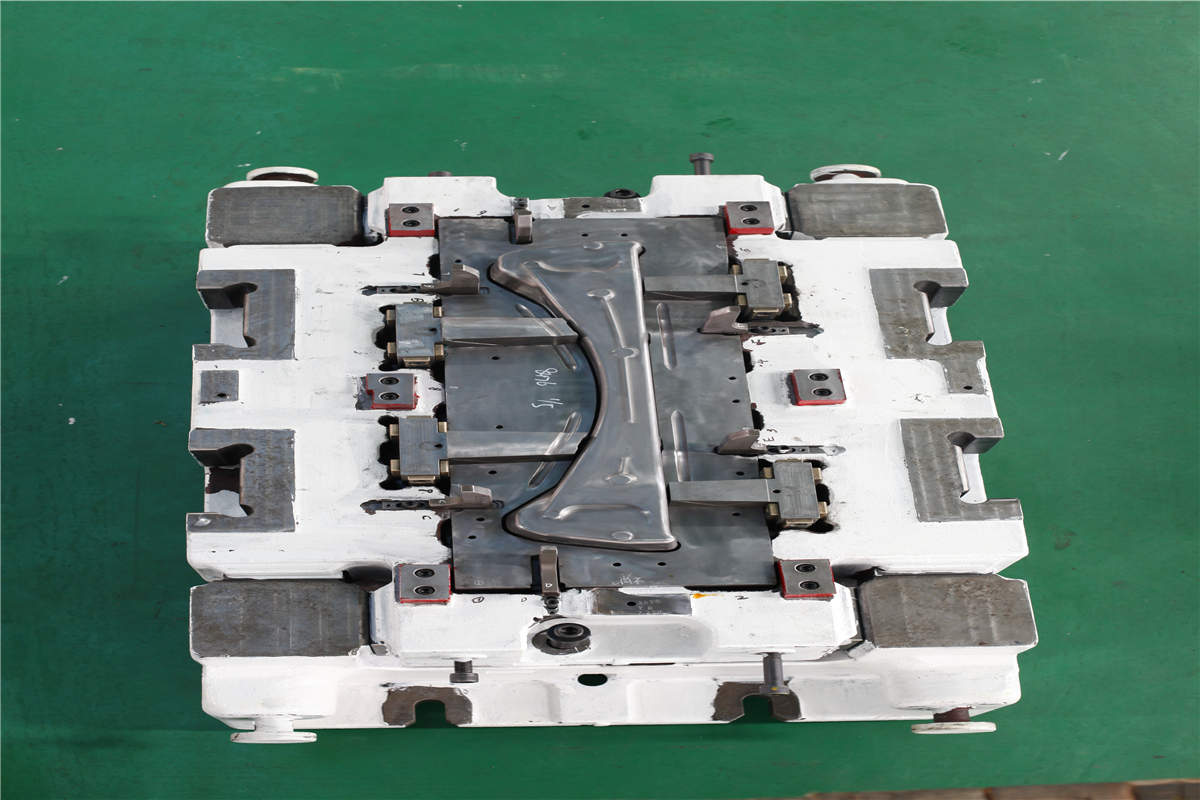

Part Name:Member Body Mounting 2ND RH

Material Grade:High tensile steel material SP782-440

Material Size:1.00mm x 736mm x 215mm

Process: 1200T Progression tool

Cavity: one part out

Technical Challenge:Spring back

◆Application: The part applicated to automotive member body mounting part

◆Complexity: Middle

Press Machine: 2000T hydraulic press, 1200T Mechanical

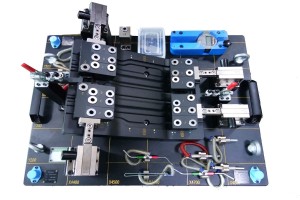

Inspection Tool: Checking fixture, CMM, Blue scanner

Lead Time: 4 months

◆Part Quality Concern: Concern over part quality issue with some high levels of spring back during part bending due to high tensile steel material, which will cause poor accuracy of matching surface areas.

Process Background:

Its material grade is SP782-440, which belongs to high strength plate, so the spring back of the part is relatively large in forming and bending. Because the material thickness of the part is 1.0mm, it is very thin, so the spring back is also large. First of all, we draw partial emboss shape, and because the material of the part is high tensile material, the spring back will also be large in bending process. Due to this, we first preliminary bending the part to solve bending done not in place. Follow step also especially left restrike stage to ensure the accuracy of part after bending stage, due to the shape of the part is more complex, with a lot of flange surface, and there are a lot of matching surface and welding surface fit together with other part, as well as the flatness requirement. After flange forming done, some surface areas with high requirement of flatness which need to restrike. The pat is complex, its corresponding hole after all of them are in shape up to standard, finally hole pierced, however some holes and stamping direction have angle which also need cam to pierce, and then ensure the part quality could meet the requirements of customers.

Conclusion:

Generally speaking, spring back is the common concern of high tensile stamping part, however we have much experience to overcome from die design to stamping part to ensure part quality.

If you have similar part and other questions, please don’t hesitate to contact us, we will be pleased to reply and discuss with you.

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our firm. These principles today more than ever form the basis of our success as an internationally active mid-size corporation for Best Price on Sheet Metal Stamping Parts - Member Body Mounting 2ND RH – Meiln , The product will supply to all over the world, such as: Berlin, New Zealand, Finland, With a state-of-the-art comprehensive marketing feedback system and 300 skilled workers' hard work, our company has developed all kinds of products ranging from high class, medium class to low class. This whole selection of fine products offers our customers different choices. Besides, our company sticks to high quality and reasonable price, and we also offer good OEM services to many famous brands.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.