Best Price on Sheet Metal Stamping Parts - Side Frame R/l, Front Back – Meiln

Best Price on Sheet Metal Stamping Parts - Side Frame R/l, Front Back – Meiln Detail:

Part Name: SIDE FRAME R/L, Front BACK

Material Grade: SPFC590

Material Size: 1.20mm x 964mm x 164mm

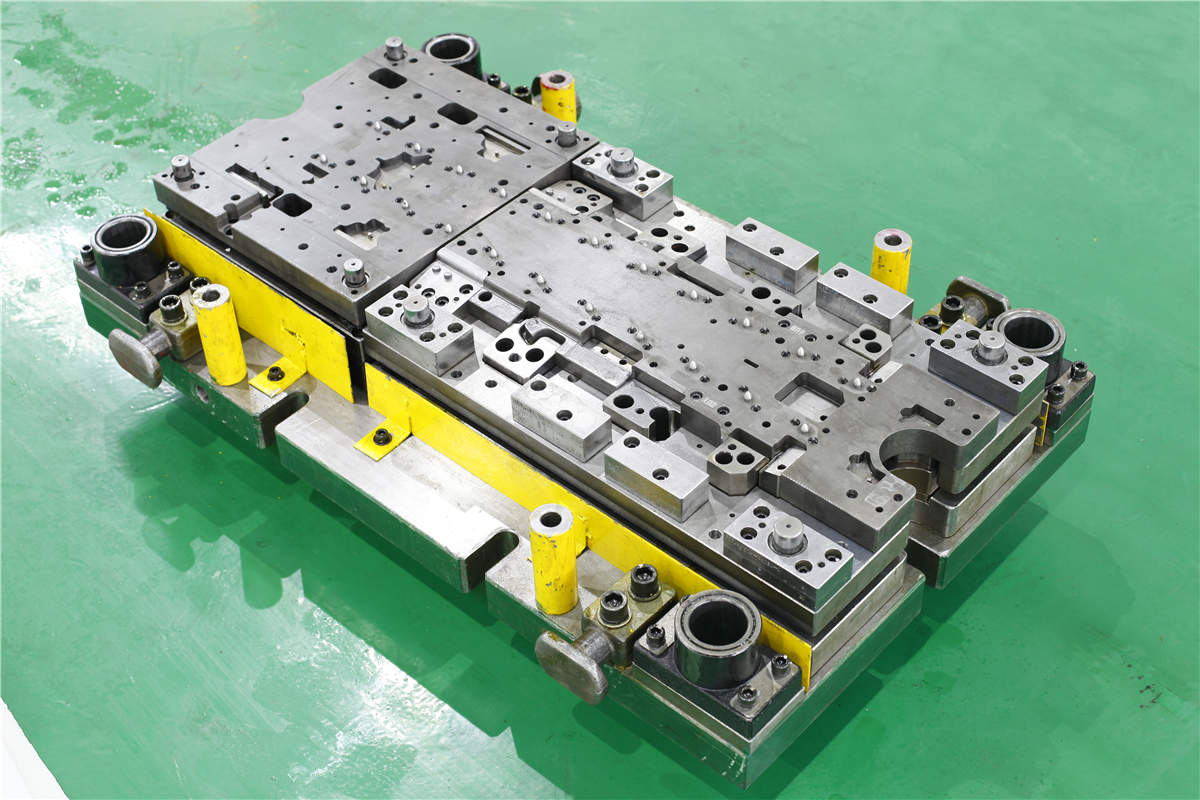

Process: 800T Progression tool

Cavity: R and L part out

Technical Challenge: Negative angle forming

◆Application: The part applicated to automotive seat part

◆Complexity: Middle

Press Machine: 2000T hydraulic press, 1200T Mechanical

Inspection Tool: Checking fixture, CMM, Blue scanner

Lead Time: 4 months

◆Part Quality: Potential risk with some of distortion and twist, thus strictly control on both end of the part quality, as well as the whole surface.

Process Background:

Some special angles on the stamping parts make it difficult to bend. This part with a bend less than 90 degrees and cannot be bent in one step. It is usually required to bend to 90 degrees first, then bend to a negative angle with less than 90 degrees, and finally to cam strike the negative angle and the surrounding emboss. Due to this, we use cams to form negative angle in blank holder and cam bend stage. Since the shape of part with negative angle, the reason why cam pierce prior to cam bend is that scrap falling out concern, otherwise the scrap will fall into the cam which cause in scrap built up.

This part is long, potential risk with some of distortion and twist on both end of the part, thus strictly tolerance control in these areas, as well as the center whole surface. Besides, material grade of this part is high tensile steel, concern over spring back during cam bend, we add a cam strike process to improve spring back.

Conclusion:

For complex stamping parts with negative angles, cams are mainly used to solve the forming problem. And in the future part with similar negative angles, we hope to explore and study a better and faster process to make negative angle forming.

If you are interested in negative angle process or have similar seat parts, please don’t hesitate to contact us, we will be pleased to discuss with you.

Product detail pictures:

Related Product Guide:

Our intention is usually to satisfy our buyers by offering golden provider, great rate and good quality for Best Price on Sheet Metal Stamping Parts - Side Frame R/l, Front Back – Meiln , The product will supply to all over the world, such as: Provence, Nairobi, Honduras, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.

A good manufacturers, we have cooperated twice, good quality and good service attitude.