Best-Selling Hydraulic Metal Stamping Press - fixture check pins – Meiln

Best-Selling Hydraulic Metal Stamping Press - fixture check pins – Meiln Detail:

Fixture secondary datum pin is used for locating part.

Steel material and surface treatment with plating.

Fixture secondary datum pin is used for locating part. Steel material and surface treatment with plating.

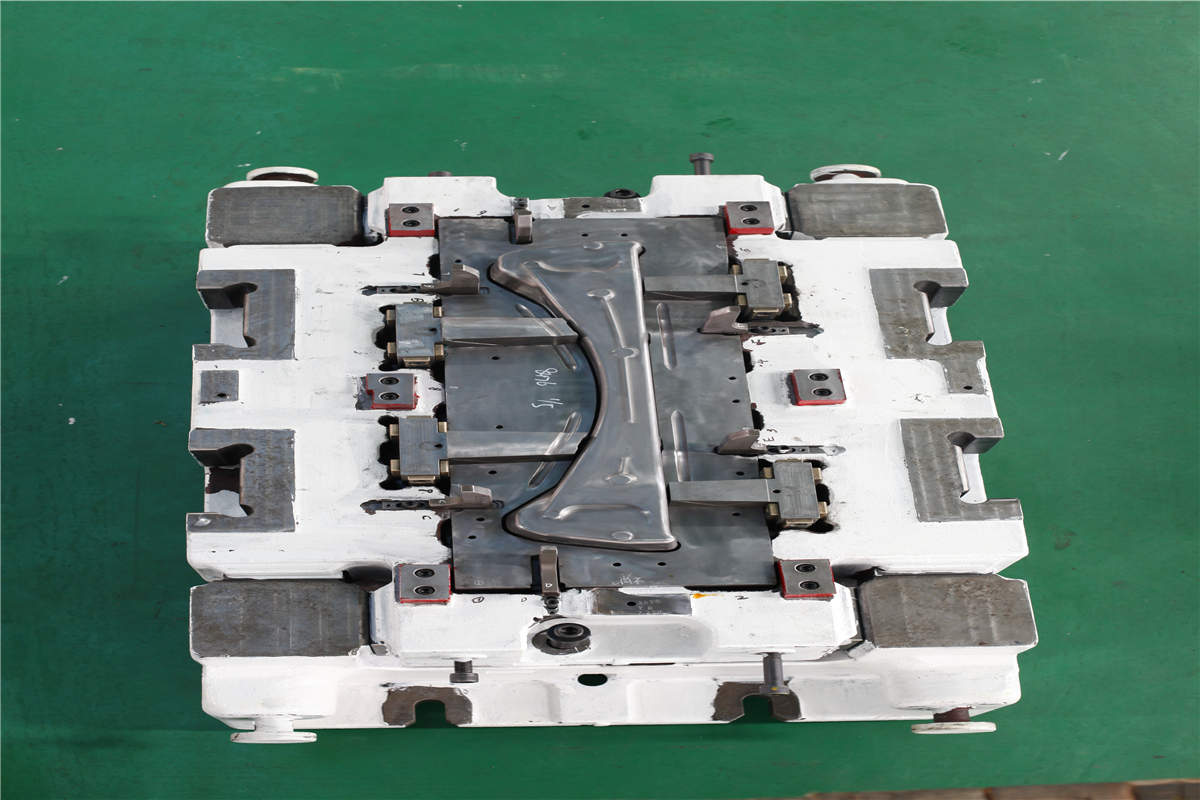

The part must be positioned before clamping and testing can begin. Locating pins are used to position the part precisely on the tool. Location of locator pins determined according to part drawings RPS system usually set two locator holes per part).

The locating pin is composed of three parts guide, locating and handle. It ensures that the guide part of the pin can enter and exit freely in the locating hole. Marking of locating pins: mark pin number and corresponding RPS point name in handle groove.

According to the RPS characteristics of the part the locating pin is correspondingly set as a cone pin (Al k, A2 k or column pin (A1z, A 2 z)

In the locating holes, guide bushings must be installed and bonded to the tester body in order to ensure accurate locating of the locating pin. According to the different requirements of the shape of the hole the structure of the locating pin and the corresponding guide sleeve can be divided into anti-rotation structure and non-rotation structure. Each dowel is configured with a 2mm wire rope and secured to the appropriate part of the specimen body.

Pin placement: The locating pin and the detecting pin shall be clamped in the corresponding spring clip on the measuring tool body after use in inspection: In assembly drawings, there must be a clear statement of pin and hole.

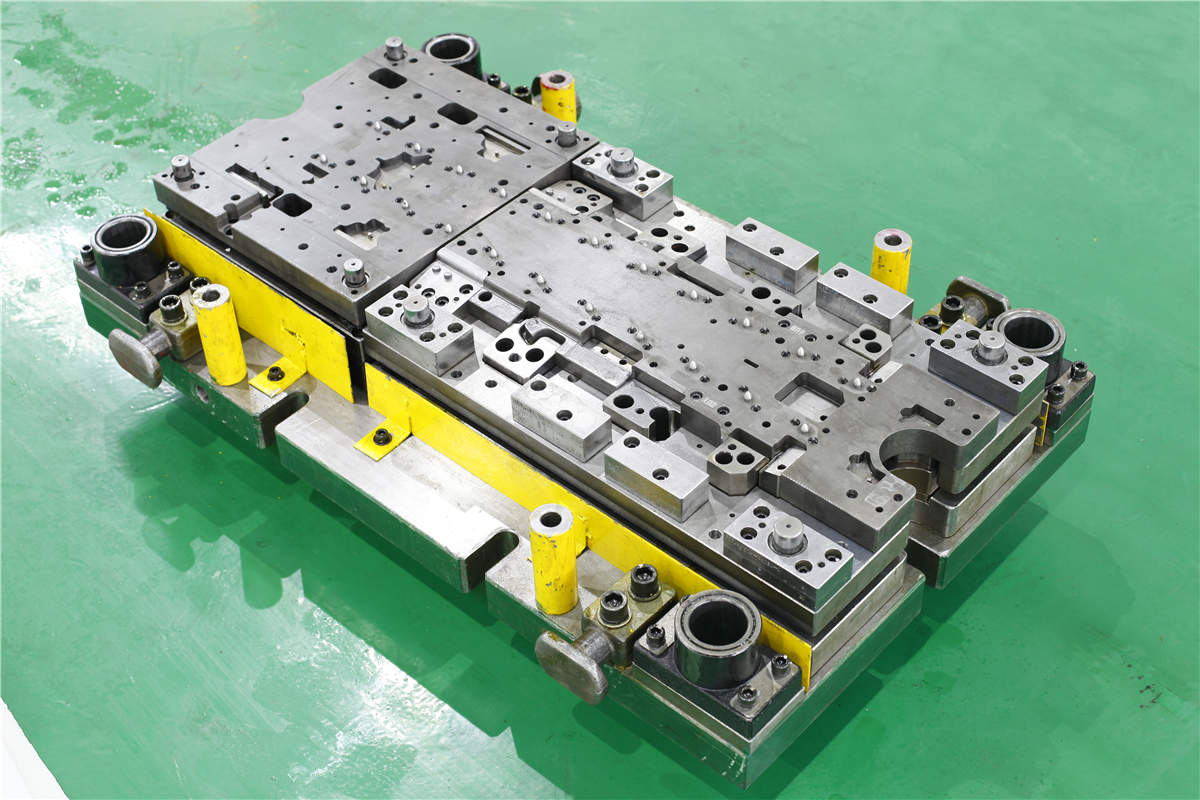

Product detail pictures:

Related Product Guide:

With our excellent administration, strong technical capability and strict excellent control method, we carry on to offer our clients with responsible good quality, reasonable costs and great companies. We intention at becoming considered one of your most responsible partners and earning your pleasure for Best-Selling Hydraulic Metal Stamping Press - fixture check pins – Meiln , The product will supply to all over the world, such as: Rotterdam, Surabaya, Iran, we have all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!