Best-Selling Welding Fixture Table - Checking Fixture – Meiln

Best-Selling Welding Fixture Table - Checking Fixture – Meiln Detail:

Aluminum alloy is the most widely used non-ferrous metal structural material in industry. It has been widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding and chemical industry. With the rapid development of automobile industry, the demand for aluminum alloy sheet metal parts and inspection tools is increasing, which makes the research on the application performance of aluminum alloy go deep.

Because the automobile checking fixture made of aluminum alloy have the following advantages:

1. Light and soft.

2. Good strength.

3. Good corrosion resistance. One of the characteristics of aluminum alloy is that a dense oxide film will be formed on the surface when contacting with air, which can prevent corrosion, so it has good corrosion resistance. If the “alumina membrane treatment method” is applied to it, it can comprehensively prevent corrosion.

4. Good processing performance.

5. Easy regeneration. The melting point of aluminum is low (660 ℃) and regeneration is simple.

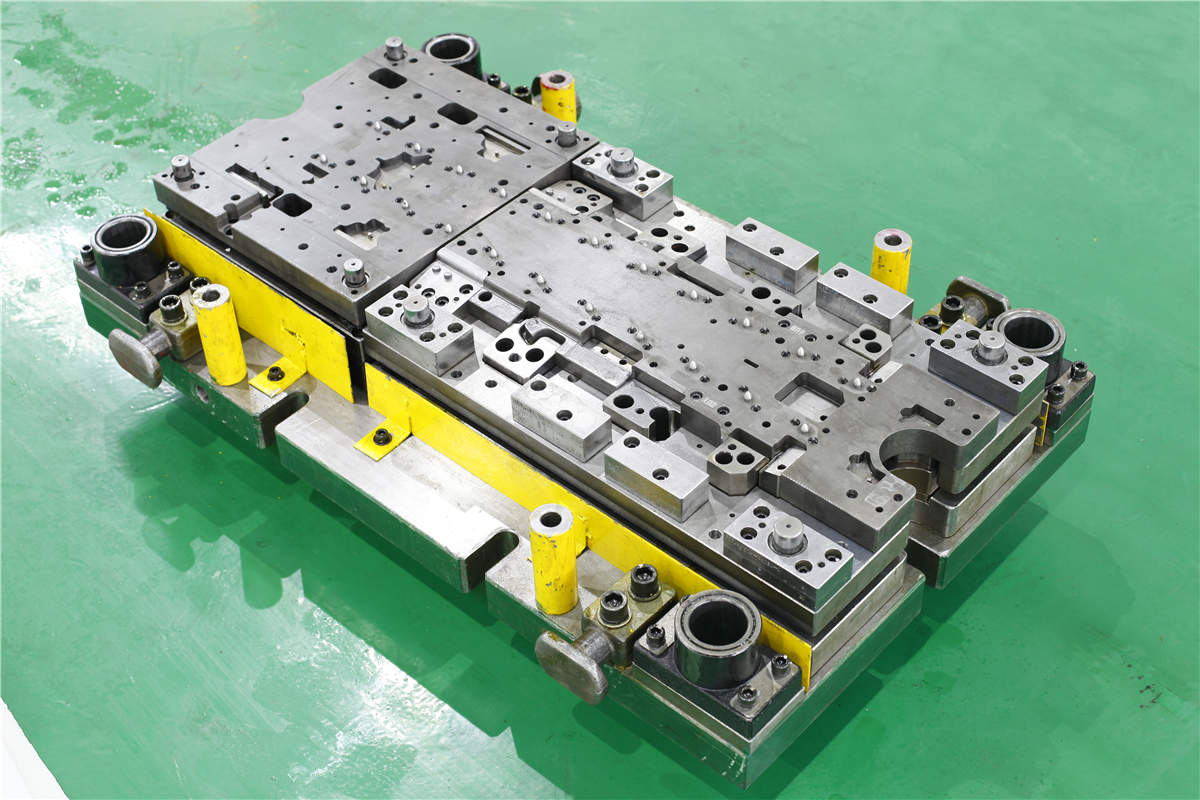

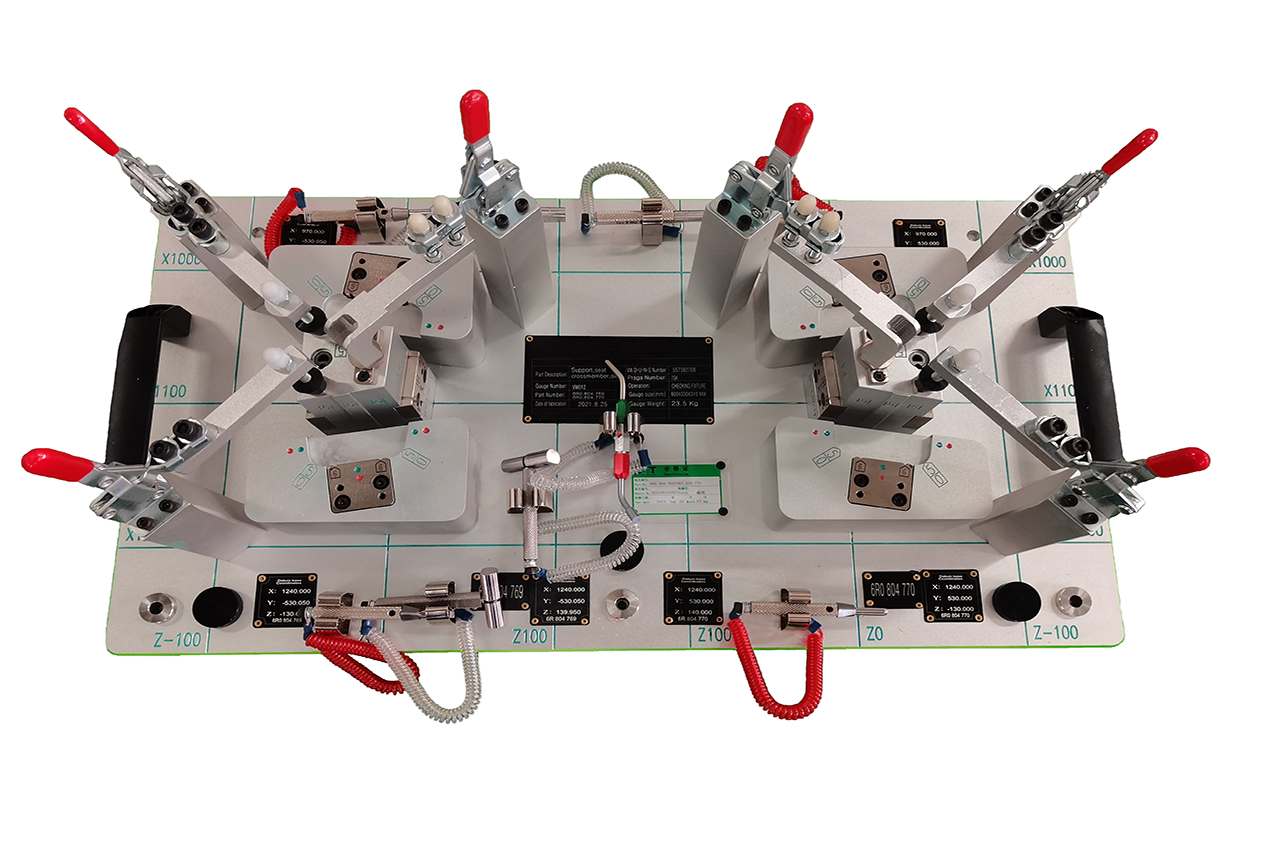

Generally speaking, the structure of checking fixture is mainly composed of the following parts: base plate, frame and simulate block, positioning device, clamping device, measuring device, auxiliary device, etc.

Both base plate and main body of the fixture are made of aluminum alloy. The simulate block always use 6061 aluminum alloy or better, should have hard anodizing. And the pins, bushes, positioning blocks and movable unit choose GCr15 Bearing steel or better, quenched and tempered for hardness no less HRC58. The support unit usually choose cast aluminum, forged aluminum and 45# carbon steel, follow structural requirements to ensure stability.

As to the size of the checking fixture depending on the size of stamping part. And the checking fixture color choice is according to customer requirement.

If you have interest or want to know more about Aluminum checking fixture, please do not hesitate to contact us. We are pleased to discuss with you.

Product detail pictures:

Related Product Guide:

We've been proud with the significant shopper fulfillment and wide acceptance due to our persistent pursuit of top of the range both of those on solution and repair for Best-Selling Welding Fixture Table - Checking Fixture – Meiln , The product will supply to all over the world, such as: Hamburg, Turkey, Angola, All of our products comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients in the near future.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!