Big discounting Checking Fixture For Auto Parts - Automotive Roof Side Part – Meiln

Big discounting Checking Fixture For Auto Parts - Automotive Roof Side Part – Meiln Detail:

Brief Description: High Strength Steel Forming

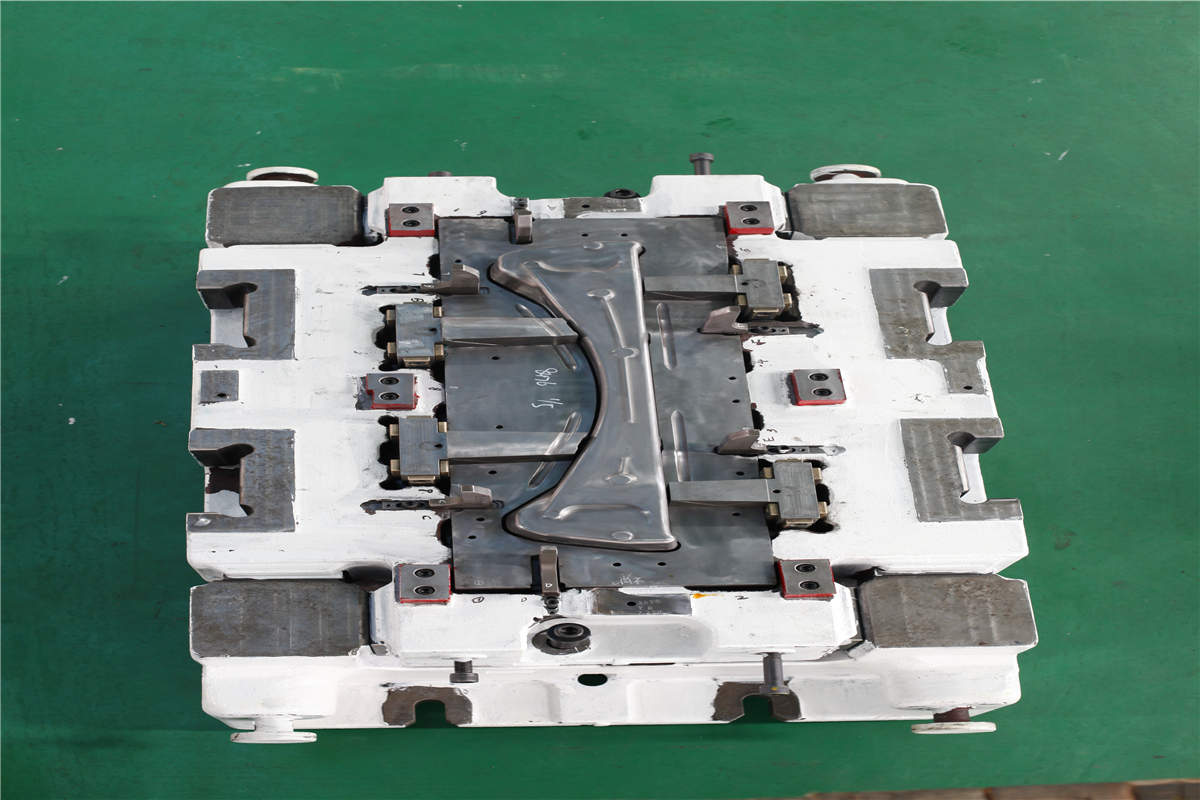

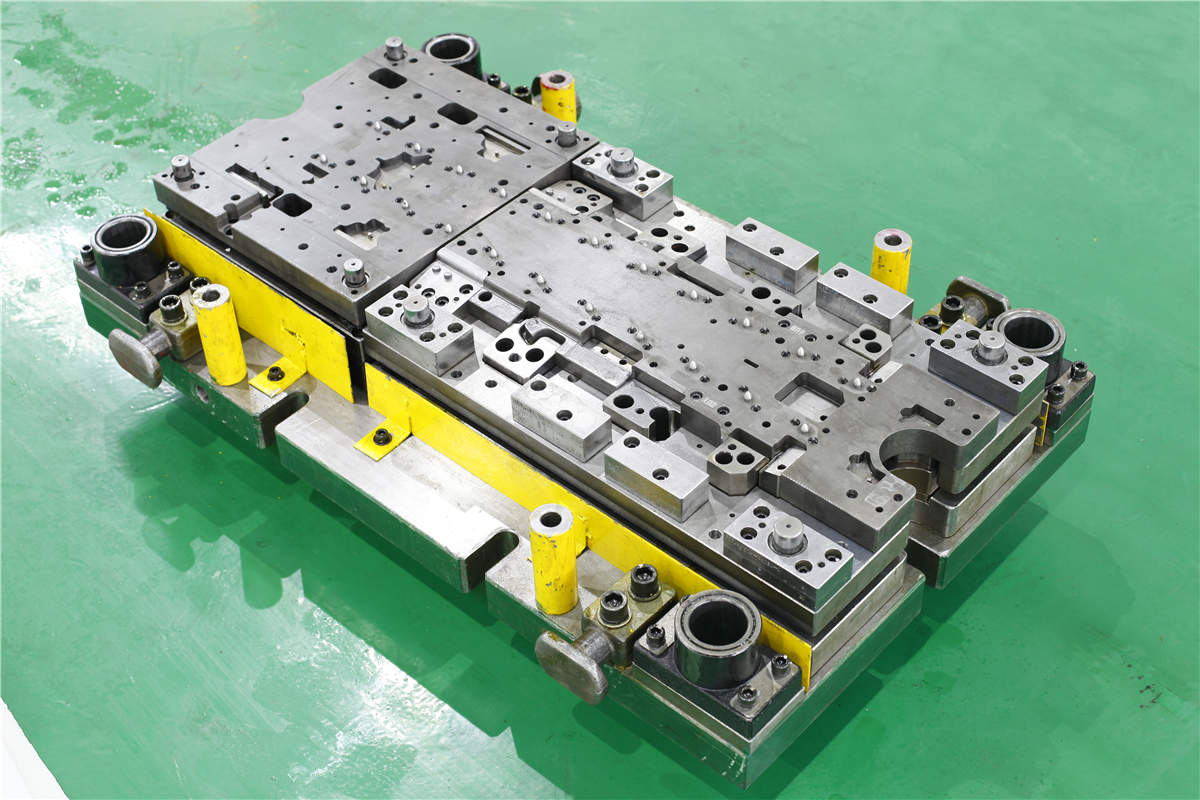

Part Name: Automotive Roof Side Part

Material Grade: Material JSC980YL

Material Size: Material size is 1.00mm x 1090mm x 165mm

Process: 1200T Progressive

Cavity: Tool cavity is Right and Left two parts out

Product Process Guidelines:

Nowadays automotive body parts use advanced high strength steel to effectively improve protection from collision, and ensure the safety, main body parts are made from high strength steel materials are lighter and fuel efficient.

Refer to automotive body parts, like beam, roof. High strength steel has been widely used, and spring back is one of the most difficult problems to overcome.

High strength steel (HSS) forming factors, die design simulation and consideration, lubrication and hardness.

Die design preparation and consideration

Generally, the beneficial properties of higher-strength materials, high yield strength, high tensile strength and high level hardness The higher stress require additional cutting clearances between the punch and die as compared to those required for mild and common steel.

Higher-strength steels require careful preparation and consideration before choosing draw forming process.

High strength steel forming requires good lubricants.

As the higher strength steels become hotter and hotter, many lubricants intend to increase their friction characteristics and retard material flow. Use correct lubricants is very important to change temperatures.

Heat treatment and surface coating for forming steel and die should be also considered fully and clearly.

Before making the virtual die, during design, we need to calculate the forces requires for forming, cutting, piercing and trimming, bending, flanging and drawing. Throughout die design, for the original layout and process, CAE simulation have to go ahead, spring back is a common problem for high strength steel and high strength alloy steel. Spring back and spring back compensation should be better to consider before design. yield strengths for mild steel and high strength steel are different, in the range of 25 to 100 ksi.

More and more auto body parts are made from high strength steels, from old 590mpa to current 1180mpa, all our plants have experience from design to trial, if you have similar products, please contact with us.

Product detail pictures:

Related Product Guide:

Well-run products, skilled income group, and better after-sales products and services; We have been also a unified massive family, all people stick with the business price "unification, dedication, tolerance" for Big discounting Checking Fixture For Auto Parts - Automotive Roof Side Part – Meiln , The product will supply to all over the world, such as: Peru, Egypt, Vietnam, Our company will continue to serve customers with best quality, competitive price and timely delivery & the best payment term! We sincerely welcome friends from all over the world to visit& cooperate with us and enlarge our business. If you are interested in our products, please do not hesitate to contact us, we will be happy to provide you with further information!

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.