Big discounting Checking Fixture For Auto Parts - Frame Front Cushion – Meiln

Big discounting Checking Fixture For Auto Parts - Frame Front Cushion – Meiln Detail:

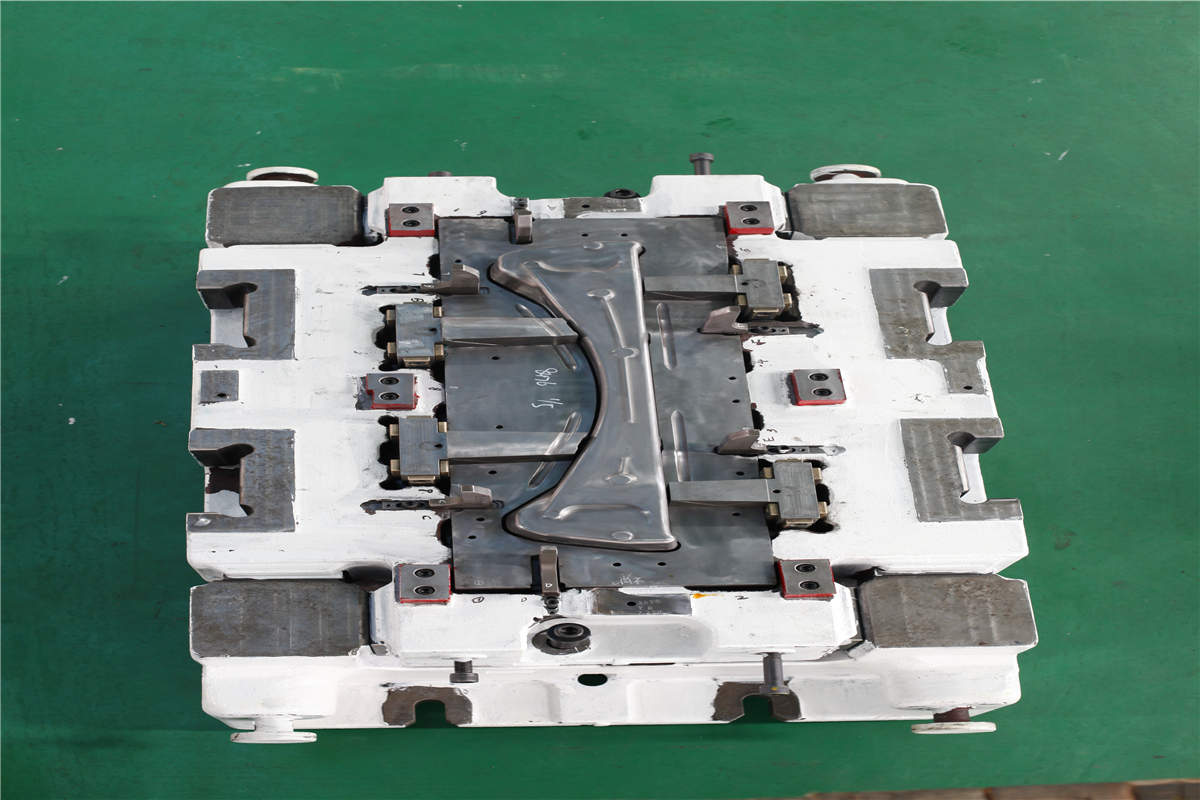

Part Name: Frame Front Cushion

Material Grade: SPCE

Material Size: 0.70mm x 566mm x340mm

Process: 300T Progression Blank & x5 Stage 200T TDM

Cavity: one part out

Complexity: Middle

◆Application: The part applicated to automotive seat frame part

◆Experience: automotive seat part

Press Machine: 300T Mechanical,630T Mechanical

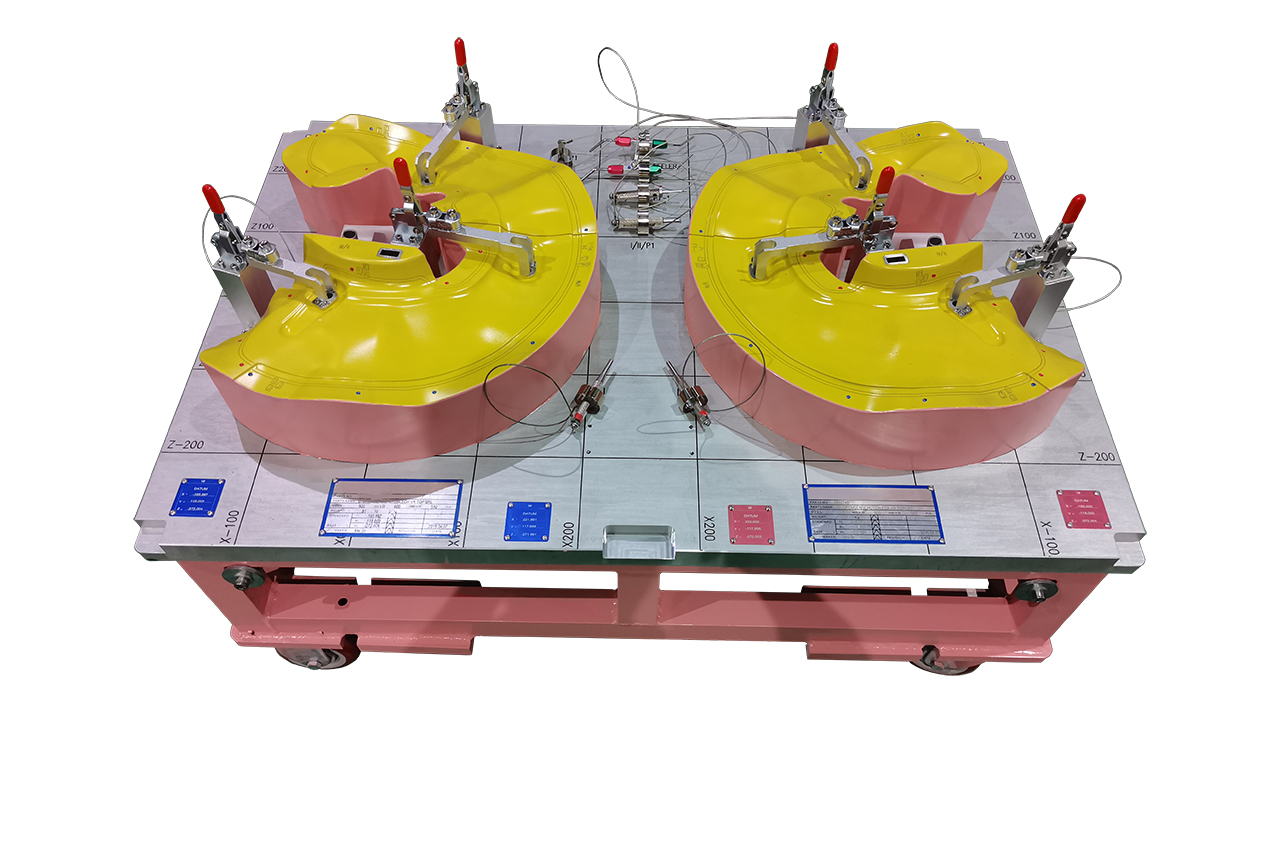

Inspection Tool: Checking fixture, CMM

Lead Time: 4 months

◆Part Quality :

Process Background:

The main body of the frame is a metal welded structure, which plays the role of shaping the seat and supporting the human body. The frame and seat cushion are generally made of sheet steel, designed according to the principles of ergonomics, with the passengers can obtain the most comfortable form requirements as the criteria.

Consider of part volume and complexity, besides 300T Progression Blank tool, our designer designed 5 sets TDM tools for this part, firstly draw, then trim-pierce, pierce-cam/trim, then bend-form, bend finally. Blanking and pierce stage separates to two stages, by this way, not only reduce blanking force, but also conducive to improve the life of the die. It is important to put pierce stage prior to form, so due to this, it helps to locate the part in the form stage. Part shape with two corners in outside areas is very easy to cause splitting issue, so a cam/trim stage is very important to be added for improving split.

Advantage:

Our company has rich experience in the automotive tool field that enables us to provide our customers with efficient and professional services and avoid possible problems in the tool process,also provide cost saving tools and provide customers with systematic solutions.

If you have any questions about auto seat frame part or TDM die, please don’t hesitate to contact me, and we are very pleased to reply and discuss with you.

Product detail pictures:

Related Product Guide:

With the "Client-Oriented" business philosophy, a rigorous quality control system, advanced manufacturing equipment and a strong R&D team, we always provide high quality products, excellent services and competitive prices for Big discounting Checking Fixture For Auto Parts - Frame Front Cushion – Meiln , The product will supply to all over the world, such as: Los Angeles, Latvia, US, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

.png)