Bottom price Jig Machining - TRF finger – Meiln

Bottom price Jig Machining - TRF finger – Meiln Detail:

TRF finger is used for picking up and transferring part when part production and running transfer simulation, which clamping force could reach 70kg.

TRF finger can reduce workers, improve efficiency, reduce costs, improve product quality and have good safety.

As to the gripper to be used, make sure, with the panel weight and dynamic energy required for transfer into considerations, that the gripper is of the type within the clamp output range. At the same time, select the most inexpensive type.

Type of Grippers

The End-of-arm has to be in contact with the objects and interact with them. Adapting these ones to the different objects and industrial activities ended with different kinds of grippers. There are four main types of robot grippers: vacuum grippers, hydraulic grippers, pneumatic grippers and servo-electric grippers.

a)Vacuum Grippers.

The vacuum gripper has been a standard tool for robots in manufacturing due to its high level of flexibility. The tool is made of polyurethane or rubber suction cup to catch the objects. There are some vacuum grippers that use closed-cells foam rubber layer, instead of the suction cups.

b)Hydraulic Grippers.

Hydraulic Grippers are the ones that can apply the most strength and often are used in applications that require a huge amount of force. The force is provided from pumps that can generate up to 13789.51 kPa. Although their strength, they are messier than any other gripper due to the oil that the pumps are using. Also they need more maintenance because of the huge amount of force that they can apply.

c)Pneumatic Grippers.

Pneumatic grippers are popular due to their light weight and compact size. They can be design for tight spaces, which can be helpful in manufacturing industry. This kind of gripper can be open and close; because of this their nickname is “bang bang” actuators,

given by the sound they do when the metal-on-metal is operating.

d) Servo-electric Grippers

The servo-electric grippers are becoming more used in the industry; thanks to their easy control. The gripper jaw movements are controlled by electronic motors. These grippers are highly flexible and good for handling different material tolerances. Also they are cost effective because they don’t have air lines and are clean.

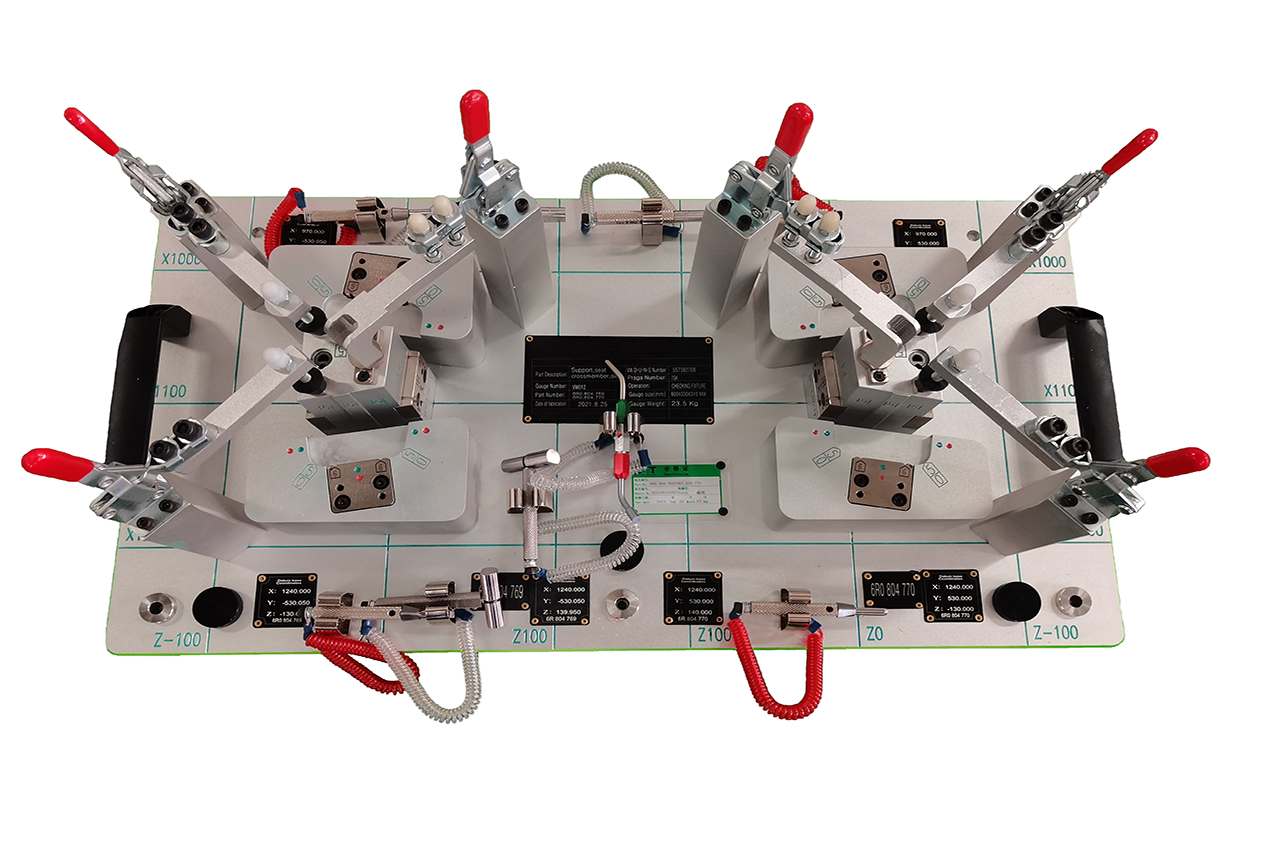

Product detail pictures:

Related Product Guide:

We generally continually give you quite possibly the most conscientious shopper company, and the widest variety of designs and styles with finest materials. These endeavours include the availability of customized designs with speed and dispatch for Bottom price Jig Machining - TRF finger – Meiln , The product will supply to all over the world, such as: kazan, Milan, Bahamas, We expect to provide products and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.