Factory Cheap Cnc Checking Fixture Components Metal Stamping Parts - Auto support part – Meiln

Factory Cheap Cnc Checking Fixture Components Metal Stamping Parts - Auto support part – Meiln Detail:

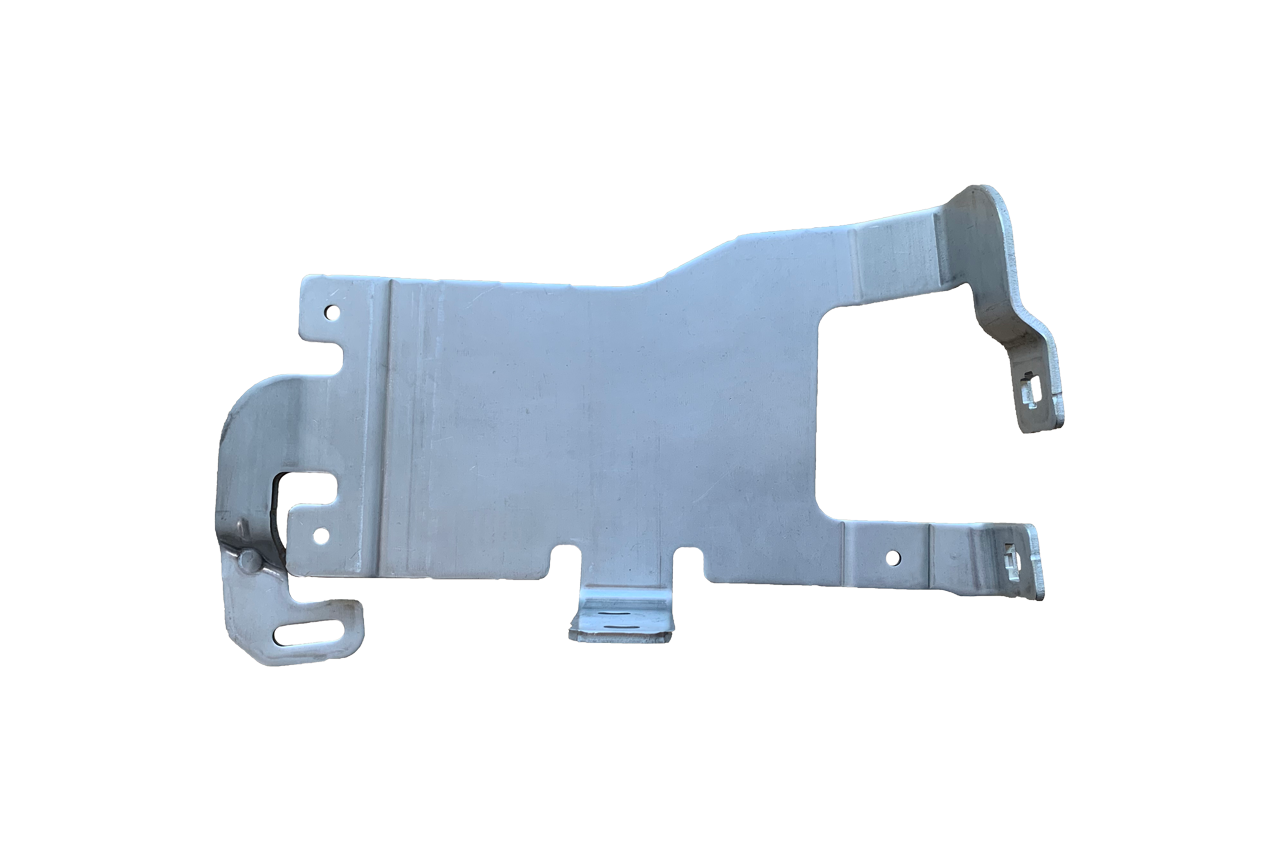

Part Name:

MPAD-STEUERGERAETE-HALTER

Material Grade: AL5-IIC-NP-UE

Material Size: 4.0mm x 362mm x 201mm

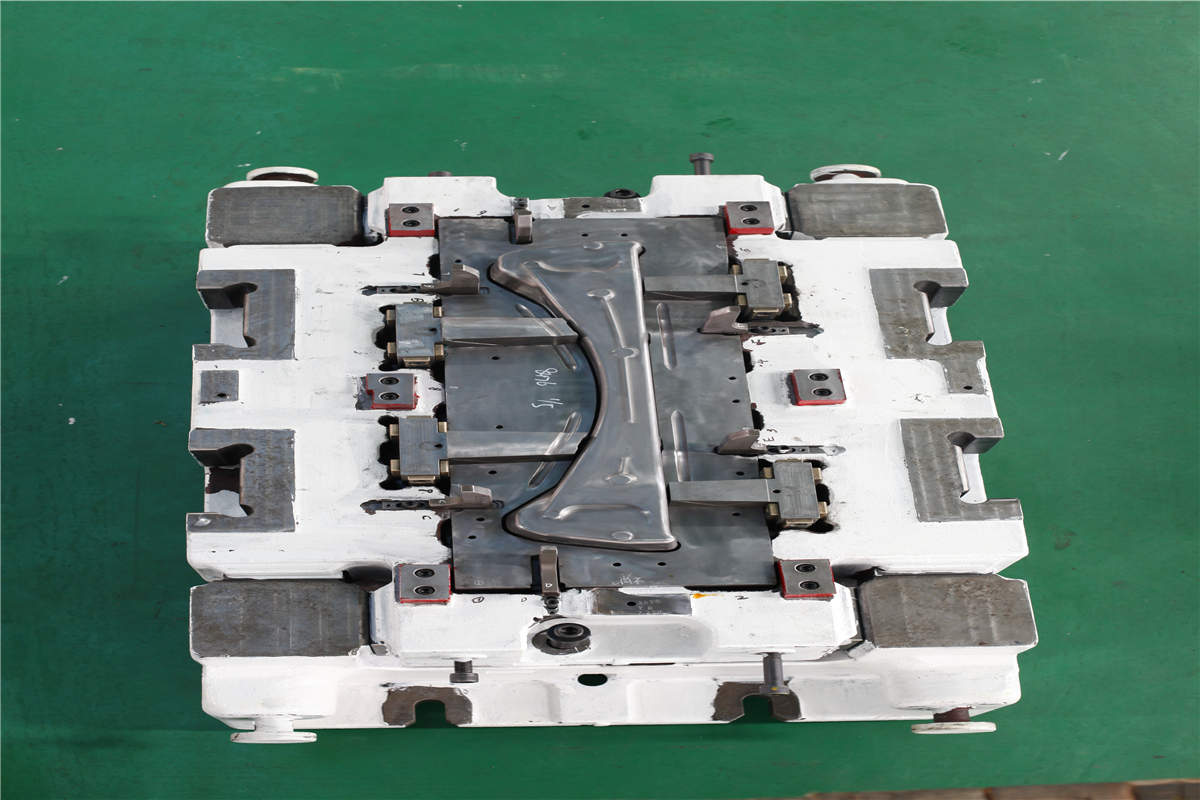

Stage Process: 500T Progressive Tool

Cavity: one part out

Press Machine: 630T, 1200T Mechanical

Inspection Tool: Checking fixture, Laser scanner

Lead Time: 3 months

Technical Challenge: Material Thickness 4.0mm

Technical Keyword: The influence of material thickness on stamping parts processing

Background:

Material thickness has a direct effect on stamping process arrangement. For example, for this part, due to the thickness of the material, under the influence of the large gap, the accuracy is low and the quality is rough. It is necessary to meet the accuracy requirements through the refurbishment process.

For this part with material thickness 4.0mm, which has a great influence on the stamping deformation force. Material thickness is proportional to stamping variation. The thicker the material, the greater the stamping deformation force. According to the size of the deformation force, we choose the right stamping equipment and strength of the die.

The dimensional accuracy of stamping parts will be affected by spring back, as well as the impact of the cutting surface. However, no matter in bending, drawing and blanking processes, the spring back of the stamping parts is greater for thin material than thick material. Although the precision of thin material parts is reduced because of the larger Spring back. So the general trend is that the dimensional accuracy decreases with the increase of material thickness.

Conclusion:

In generally, the influence of material thickness on stamping process, parameters, die structure, dimensional accuracy and stamping deformation force. In the actual production process, if we find problems, we will immediately make targeted treatment, to ensure that part quality to meet customer requirements, and ensure the quality of the tool.

If you have interest or want to know more about thicker material stamping part, please do not hesitate to contact us. We are pleased to discuss with you.

Product detail pictures:

Related Product Guide:

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for Factory Cheap Cnc Checking Fixture Components Metal Stamping Parts - Auto support part – Meiln , The product will supply to all over the world, such as: Lebanon, Washington, Toronto, Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

.png)