Factory making Jig And Checking Fixture For Auto Parts - Flange, Exhaust Manifold, No.1 – Meiln

Factory making Jig And Checking Fixture For Auto Parts - Flange, Exhaust Manifold, No.1 – Meiln Detail:

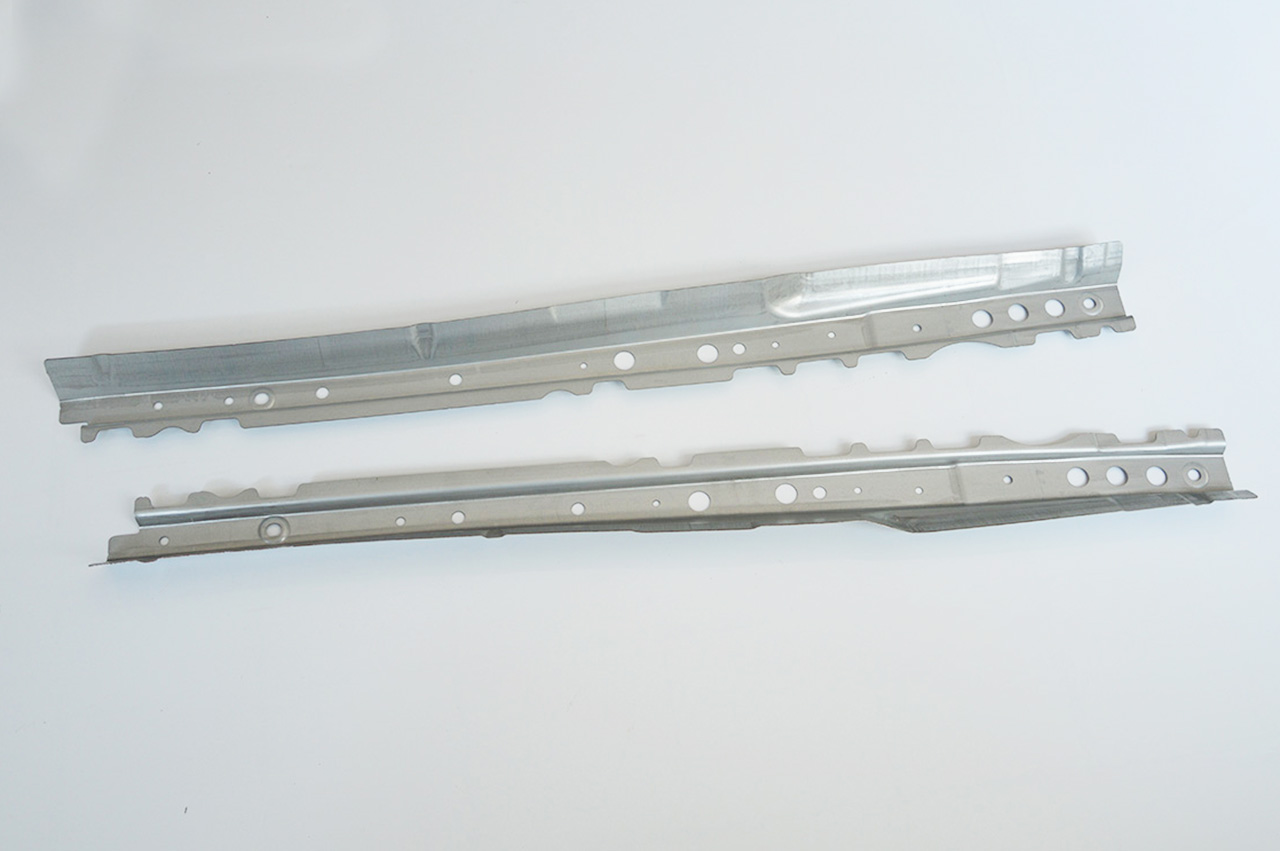

Part Name: FLANGE, EXHAUST MANIFOLD, NO.1

Material Grade: SPH270C-OD

Short/Brief description

Flange, exhaust manifold connect part

Material Size: 2.60mm x 323mm x 95mm

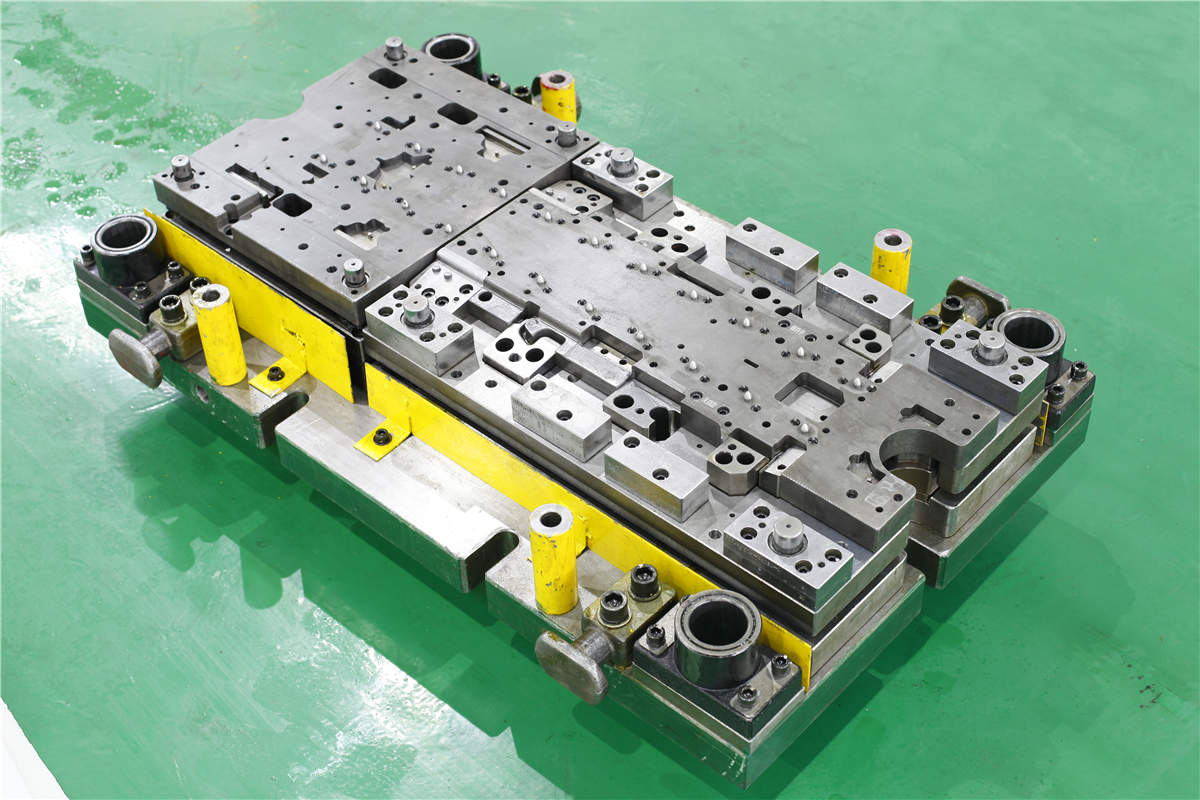

Process: X8 Stage 800T TRF

Cavity: one part out

Complexity: High

◆Application: The part applicated to automotive exhaust manifold connect part

Press Machine: 2000T hydraulic press, 1200T Mechanical

Inspection Tool: Checking fixture, CMM, Laser arm scan

Lead Time: 4 months

◆Part Quality Concern: Extremely high requirement for x4 burr holes because it is very important for sealing performance with connecting exhaust manifold port.

Background:

This part is produced by 8 stages process, 1st draw,2nd draw, 3th trim, 4th trim,5th bend, 6th cam trim, 7th cam trim and 8th separate-cam trim. As we can see, there are four holes in the part which is for manifold port to connect. The inlet flange surface is designed with a whole convex surface that is higher than the inlet flange surface, the airway hole is distributed on the convex surface, and the flange is connected with the cylinder head through the convex surface. Because the whole convex surface is the same shape to the whole concave surface, thus the whole convex surface and concave surface can be stamped in the same time, which is convenient for processing and manufacturing, and the edge of the flange body is also provided with flanging, not only can increase the structural strength of the flange body, but also can be welded bracket or fitted other parts in the flange edge.

For the four burr holes, its burr height is quite strict requirement for our customer, however our process provided a good result to this part, which final part shown a good quality with these four holes for its tolerance.

Advantage:

Our company have much experience with exhaust manifold parts and its connecting parts like flange parts, also with forming simulation, good process and processing technology for these parts from professional designers.

If you are interested in similar parts or other exhaust manifold parts, please don’t hesitate to contact me, and we are very pleased to reply and discuss with you.

Product detail pictures:

Related Product Guide:

We thinks what buyers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better high-quality, reduced processing costs, charges are more reasonable, won the new and outdated consumers the support and affirmation for Factory making Jig And Checking Fixture For Auto Parts - Flange, Exhaust Manifold, No.1 – Meiln , The product will supply to all over the world, such as: Serbia, Slovakia, Turkey, Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We're doing everything to supply our customers with best services and best solutions . We promise that we are going to be responsible all the way to the end once our services begin.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!

.png)