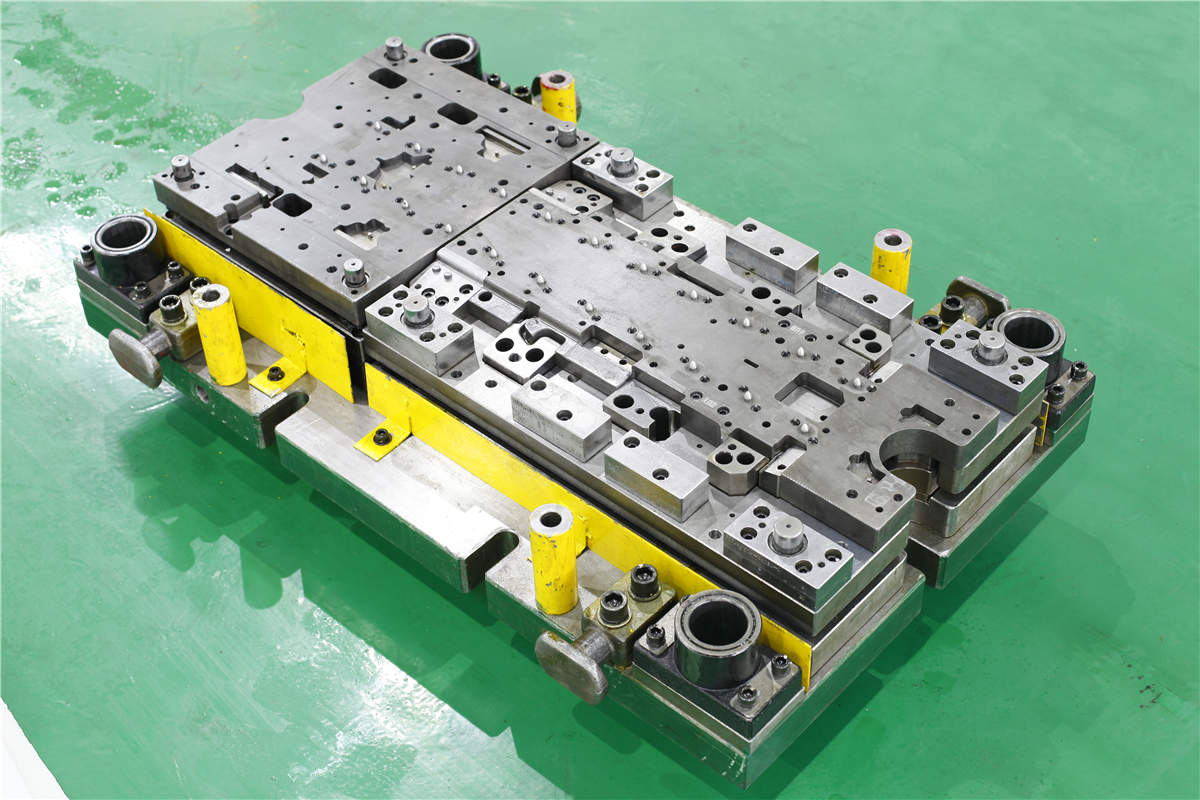

Hot New Products Stamping Metal Parts Checking Fixture - Member Body Mounting 2ND RH – Meiln

Hot New Products Stamping Metal Parts Checking Fixture - Member Body Mounting 2ND RH – Meiln Detail:

Part Name:Member Body Mounting 2ND RH

Material Grade:High tensile steel material SP782-440

Material Size:1.00mm x 736mm x 215mm

Process: 1200T Progression tool

Cavity: one part out

Technical Challenge:Spring back

◆Application: The part applicated to automotive member body mounting part

◆Complexity: Middle

Press Machine: 2000T hydraulic press, 1200T Mechanical

Inspection Tool: Checking fixture, CMM, Blue scanner

Lead Time: 4 months

◆Part Quality Concern: Concern over part quality issue with some high levels of spring back during part bending due to high tensile steel material, which will cause poor accuracy of matching surface areas.

Process Background:

Its material grade is SP782-440, which belongs to high strength plate, so the spring back of the part is relatively large in forming and bending. Because the material thickness of the part is 1.0mm, it is very thin, so the spring back is also large. First of all, we draw partial emboss shape, and because the material of the part is high tensile material, the spring back will also be large in bending process. Due to this, we first preliminary bending the part to solve bending done not in place. Follow step also especially left restrike stage to ensure the accuracy of part after bending stage, due to the shape of the part is more complex, with a lot of flange surface, and there are a lot of matching surface and welding surface fit together with other part, as well as the flatness requirement. After flange forming done, some surface areas with high requirement of flatness which need to restrike. The pat is complex, its corresponding hole after all of them are in shape up to standard, finally hole pierced, however some holes and stamping direction have angle which also need cam to pierce, and then ensure the part quality could meet the requirements of customers.

Conclusion:

Generally speaking, spring back is the common concern of high tensile stamping part, however we have much experience to overcome from die design to stamping part to ensure part quality.

If you have similar part and other questions, please don’t hesitate to contact us, we will be pleased to reply and discuss with you.

Product detail pictures:

Related Product Guide:

Our merchandise are broadly identified and trusted by end users and can satisfy continually developing economic and social requires for Hot New Products Stamping Metal Parts Checking Fixture - Member Body Mounting 2ND RH – Meiln , The product will supply to all over the world, such as: France, Tunisia, New York, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end goods, to do experienced products and solutions.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.

.png)