Hot Sale for Precision Metal Stamping Parts - Water Box, Front Part – Meiln

Hot Sale for Precision Metal Stamping Parts - Water Box, Front Part – Meiln Detail:

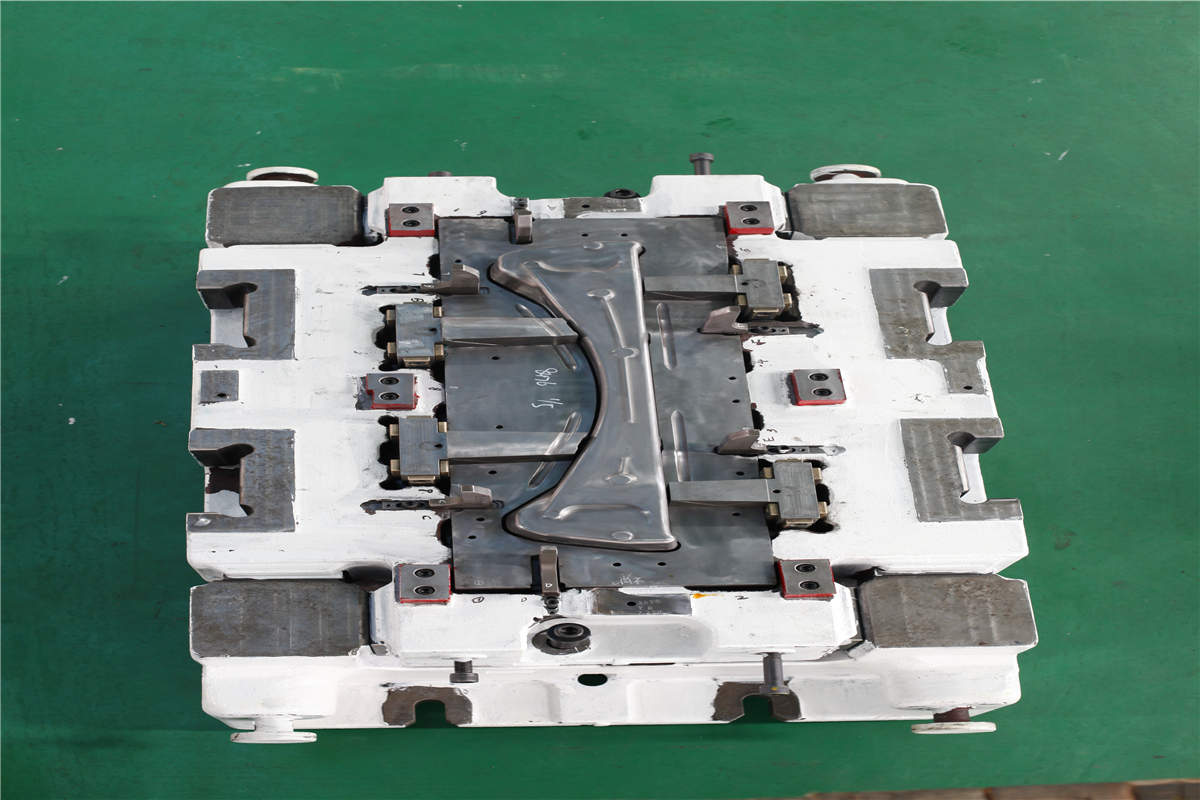

Part Name: Water box, front part

Material Grade: HDG H 220 BD+Z100 MBO IMP

Material Size: 0.60mm x 1120mm x500mm

Process: x3 Stage 400T

Cavity: one part out

Technical Challenge:

Countermeasure to wrinkle

◆Application: The part applicated to automotive water box front part

◆Complexity: Middle

Press Machine: 630T Mechanical, 1200T Mechanical, 2000T hydraulic press

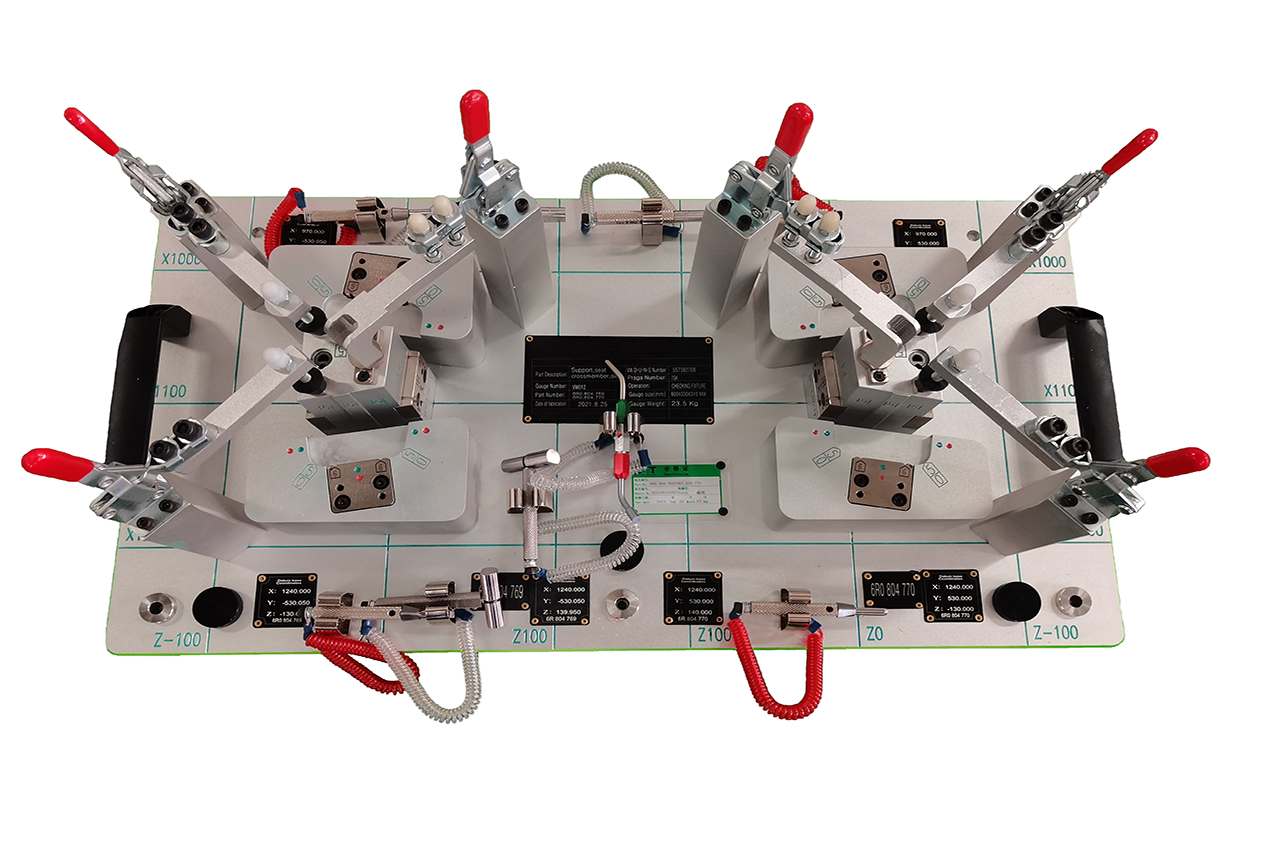

Inspection Tool: Checking fixture, CMM, Blue scanner

Lead Time: 4 months

◆Part Quality: Potential risk with wrinkle, thus strictly control on trim line of the part quality, as well as the surface tolerance.

Process Background:

This part material thickness is only 0.6mm, which is very thin and potentially causes wrinkle issue if forms directly. Therefor we design this part to draw first, then most shape of the part is done by drawing process, however this part is complex with some special areas, so material flow is uneven during drawing, which cause in wrinkle in some special areas. After further die modification and adjustment, we think the wrinkle areas should be transferred to process scrap area, then cut off the wrinkle areas in trim stage. However trim process has two stages, in other words, trim and trim two stages line up on one die, by this way, not only save die set quantity but also reduce die cost and production cost. Finally bend the outside part, part change in some especially sensitive areas during bending, as long as change minor trim line will affect the sensitive areas bended not in place so that hard to meet the tolerance of customer requirement. In further review and discussion, we change the process several times

and modify the die to ensure the part quality with these special and sensitive areas. In last, final try out part quality shows no wrinkle and tolerance met customer standard.

Conclusion:

For complex stamping parts with thin material thickness and sensitive form areas, we should try to review and design the process better as possible as in the early time, so that the times of die modification and die tuning could be less, and can ensure the part with good quality.

If you have similar seat parts or other questions, please don’t hesitate to contact us, we will be pleased to discuss with you.

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand abroad business" is our progress strategy for Hot Sale for Precision Metal Stamping Parts - Water Box, Front Part – Meiln , The product will supply to all over the world, such as: Surabaya, Romania, Swiss, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our products are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

We have been looking for a professional and responsible supplier, and now we find it.

.png)