Massive Selection for Car Spare Parts Checking Fixture Components - Automotive Side Beam Product – Meiln

Massive Selection for Car Spare Parts Checking Fixture Components - Automotive Side Beam Product – Meiln Detail:

Brief Description: Hot forming application for automotive product

Part Name: Automotive Side Beam Product

Material Grade: Material JSC980YL with hot forming

Material Size: Material size is 1.00mm x 1090mm x 165mm

Process: Hot Forming

Cavity: Tool cavity is 1 Part Out

Technical Introduction:

With the requirements for weight reduction and offering equivalent stiffness, high strength, good accuracy and behavior, direct hot forming become the most commonly used process, becomes important for the automotive industry in meeting specific requirements for higher crash safety and weight reduction.

Automotive application:

Automotive structural body parts like A/B-pillars, front and rear bumper beams, door beams, side-rails, roof rails and roof frames.

Advantage:

Highly complex part geometries can be achieved;

Weight reductions with same stiffness;

Crash performance and characteristic highly improved;

Part and product quality accuracy;

In hot forming, the part is austenitized at a higher temperature, transferred to the cooled die and then deep-drawn. In this way, complex shapes can be achieved as the material has excellent formability at high temperatures.

˜Cold and hot forming comparison

Compared with commonly used cold forming, what is the difference between hot forming? From durability. flexibility. cost-effectiveness.

The key factor to decide to use cold forming or hot forming is steel material grade. The properties of certain metal grades sometimes dictate whether you should have them hot or cold formed.

For similar grades, cold rolled metal can be stronger than hot rolled metal because of what’s called work hardening.

Generally speaking, cold forming usually results in better, more attractive finished surfaces with closer tolerances. It can be adopted into a wide range of shapes that could be easily galvanized, painted, or powder coated during the forming process.

Conclusion:

For the part, considering steel material grade- JSC980YL, and structural for reinforcing beam, we compared the process, hot forming and cold forming. The key merit for hot forming is to improving the spring back, while investment increased due to huge furnace, plunger cost and manpower.

Of course, the process to be used in the right product is the valuable job. If you need to know more about hot forming in automotive products, please contact with us.

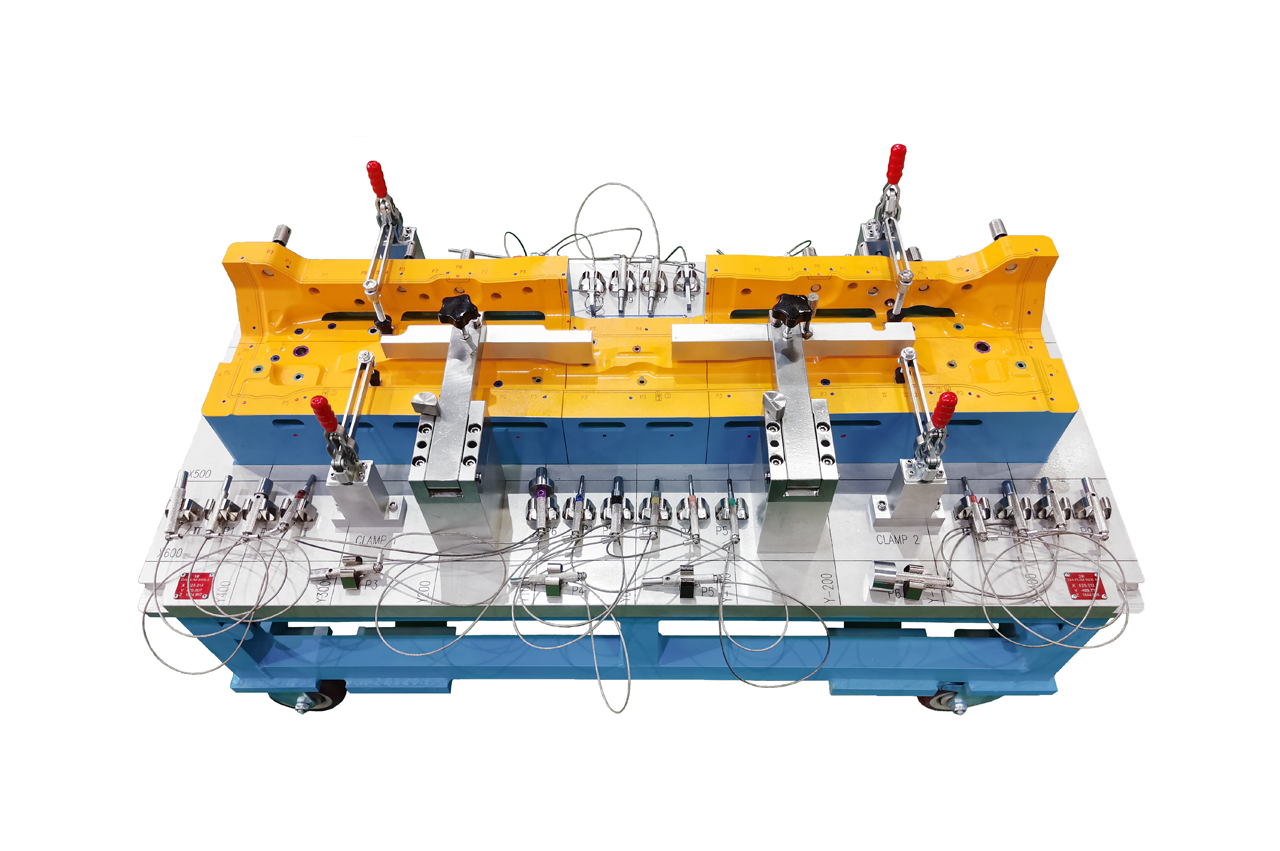

Product detail pictures:

Related Product Guide:

Sticking to the belief of "Creating products of high quality and making friends with people from all over the world", we always put the interest of customers in the first place for Massive Selection for Car Spare Parts Checking Fixture Components - Automotive Side Beam Product – Meiln , The product will supply to all over the world, such as: Jeddah, Costa rica, Suriname, Over the years, with high-quality solutions, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We offer high quality product and competitive price, welcome the regular and new customers cooperate with us!

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.