Massive Selection for Car Spare Parts Checking Fixture Components - Automotive Side Support Child Part – Meiln

Massive Selection for Car Spare Parts Checking Fixture Components - Automotive Side Support Child Part – Meiln Detail:

Brief Description: Steel die and casting die difference

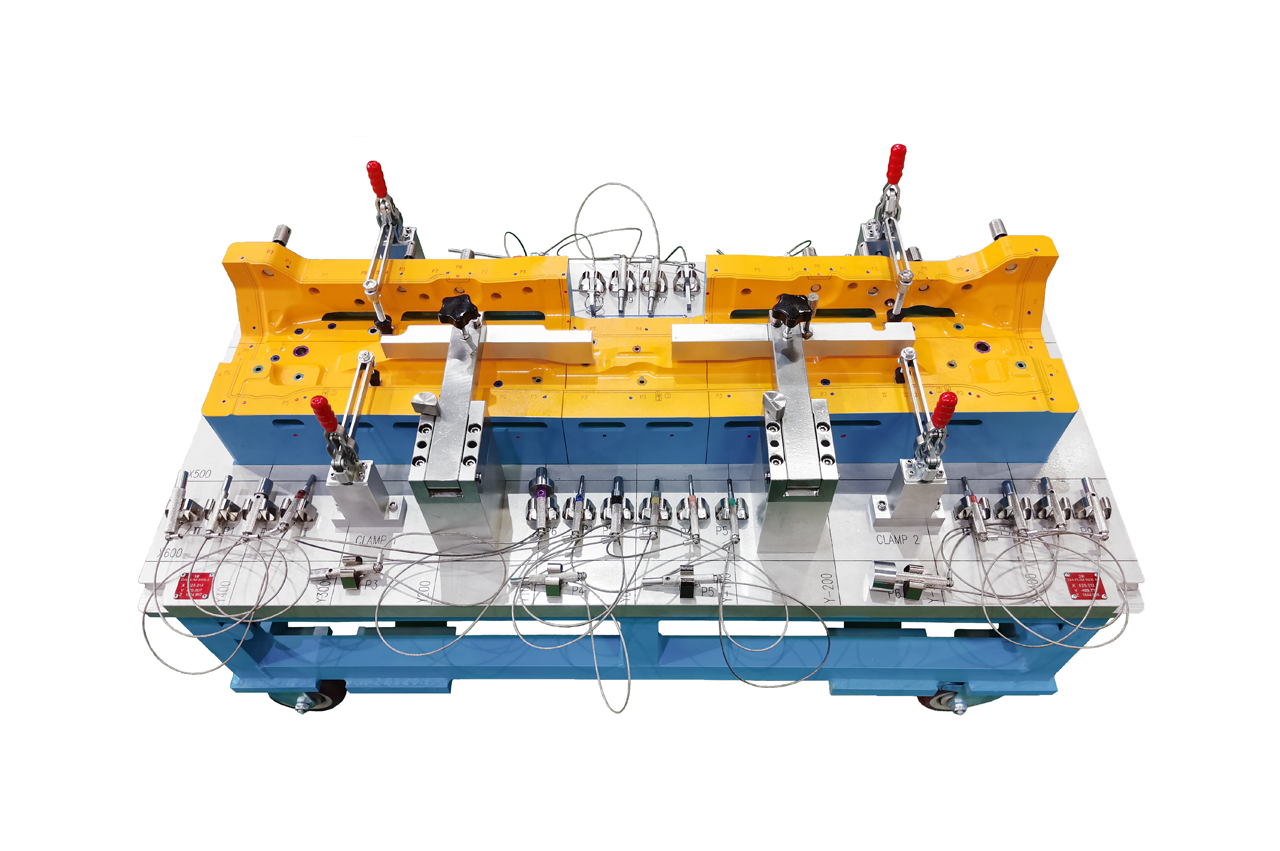

Part Name: Automotive Side Support Child Part

Material Grade: Aluminum material RC5754

Material Size: Material size is 1.00mm x 1570mm x 298mm

Process: Process stages 600ton Progressive Blanking and 1500ton Transfer with 5 stages

Cavity: Tool cavity is Right and Left two parts out

Inspection Tool: Checking Fixture and Blue Scanner

Lead Time: 4 months

Die stamping process difference

This part produced by 1500ton Transfer dies with 5 operations, which is made of casting.

Casting die is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity, which is created by using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold. Most die castings are made from non-ferrous metals, like zinc, copper, aluminum, lead, pewter, and tin-based alloys.

Advantages:

-Good dimensional accuracy

-Smooth surface

-Better strength and long lift-time

-Reduction for secondary machining operations.

Steel die is a process that assembled mainly with metal components, like upper and lower pad, stripper, holder, support plate, outer pillar, guide, inserts…

Advantages:

-Design simple

-Short lead time

-Lower investment

-Standard components

-Reduction weight

Technical Summary:

This aluminum product facing distortion and twist problems due to material grade and shape, also splitting in the side areas.

The origin forming simulation showed high risk of material decreasing, even splitting, which is out of our expectation.

Compared with distortion, splitting seems much more difficult to overcome, modify the radius, change trim line, all FCR solutions have been rejected. The surround connecting match parts will interference easily with any change. Reducing material then added, adding material then cut out… stages limit due to mass production press specification. It seems hard to find best solution to improve thinning.

Finally, we collected all data, forming, drawing, flange, hole accuracy, discussion by technical team, the product finished in a good quality, also good condition in mass production.

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Massive Selection for Car Spare Parts Checking Fixture Components - Automotive Side Support Child Part – Meiln , The product will supply to all over the world, such as: Kyrgyzstan, Karachi, Rwanda, With high quality, reasonable price, on-time delivery and customized & customized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!