New Fashion Design for Precision Stamping Parts - Reinforcement Sill Outer Rear – Meiln

New Fashion Design for Precision Stamping Parts - Reinforcement Sill Outer Rear – Meiln Detail:

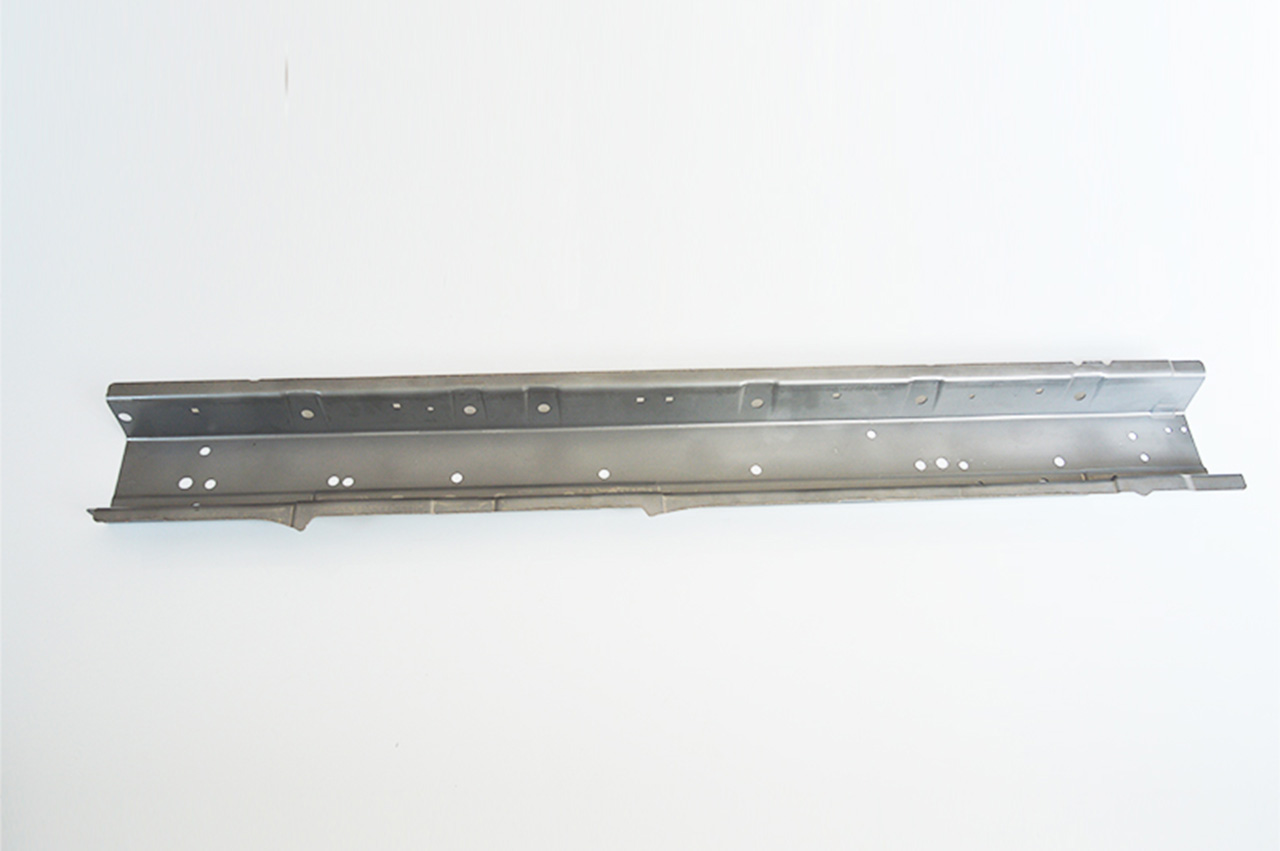

Part Name: Reinforcement Sill Outer Rear

Material Grade: RP783-780

Material Size: 1.6mm x 1400mm x 445mm

Process: 1000T Progression Blank & x3 Stage 3000T TRF

Cavity: R and L two part out

Complexity: Middle

◆Application: The part applicated to automotive sill reinforcement part

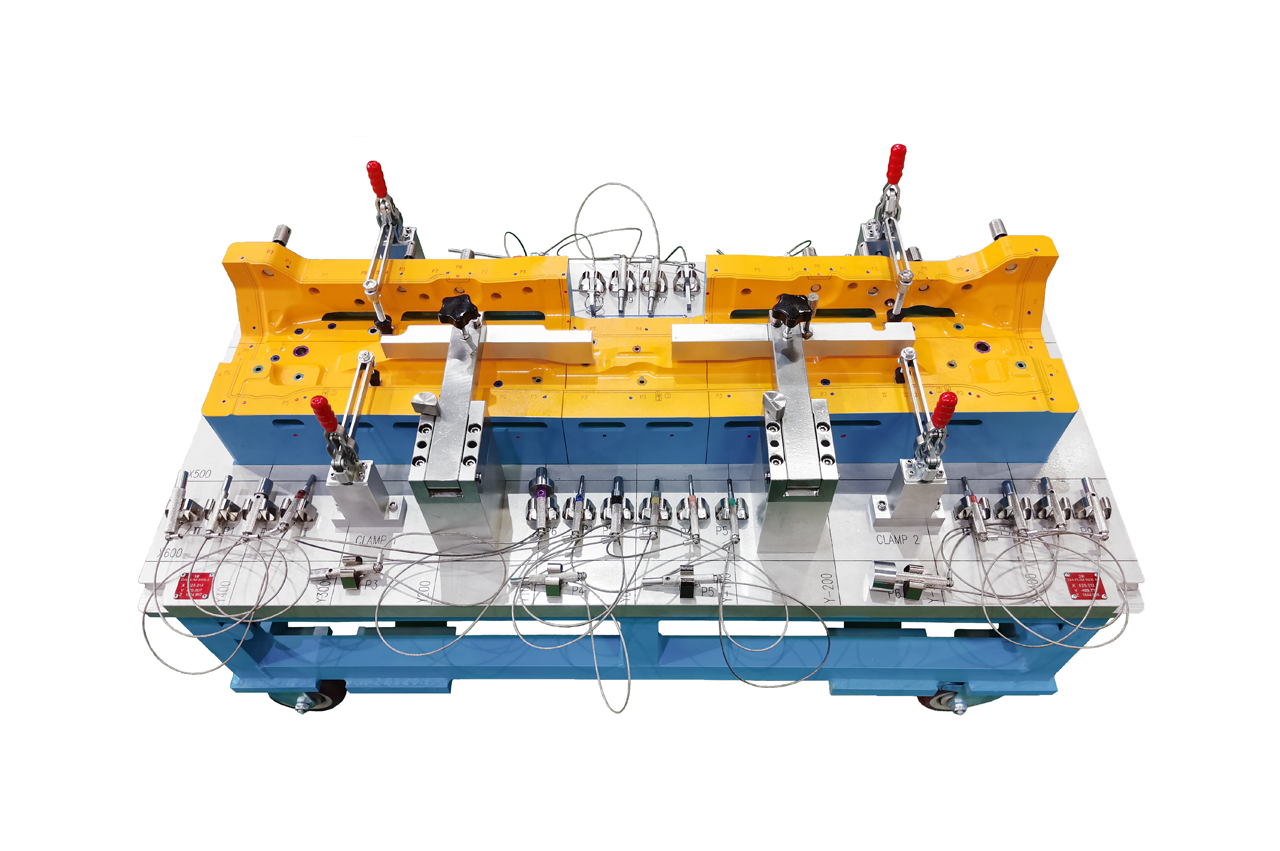

Press Machine: 2000T hydraulic press, 1200T Mechanical

Inspection Tool: Checking fixture, CMM, Laser arm scan

Lead Time: 4 months

◆Technical Challenge: Spring back for high strength steel

◆Part Quality: Extremely high requirement for side wall and flange surface

Process Background:

The automobile sill reinforcement part is made of high strength steel, and there are many quality issues such as spring back and distortion. This part flange surface is used for the assembly surface, in order to ensure the matching surface, extremely high requirement for side wall and flange surface. The process of this part is first pre-form, then cam restrike, finally pierce-cam pierce. This method can control the flatness of flange surface and the side wall of the spring back, which is conducive to the modification of part quality.

The key point that really affects the spring back amount is the modeling of the part itself. When the spring back amount of the part is large, it is necessary to use the way of spring back compensation to offset the size deviation caused by the spring back. However, when the side wall is modified, the flatness of the bottom surface must be ensured before the side wall spring back can be modified. The solution to the spring back issue of the side wall and flange surface is usually to implement spring back compensation in the flanging and restrike process, and offset the spring back amount by spring back compensation.

Advantage:

We have much rich experience with high tensile steel part and the countermeasure of spring back, also the early time forming simulation for solve part quality such as wrinkle, split, thinning and spring back, ect.

If you have similar parts with spring back issue of flanging and side wall, please don’t hesitate to contact me, and we will be pleased to reply you.

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with New Fashion Design for Precision Stamping Parts - Reinforcement Sill Outer Rear – Meiln , The product will supply to all over the world, such as: Lithuania, Salt Lake City, Kuala Lumpur, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.