OEM manufacturer Metal Stamped Part - Automotive Side Sill plate – Meiln

OEM manufacturer Metal Stamped Part - Automotive Side Sill plate – Meiln Detail:

Brief Description: Progressive Tool and Transfer Tool difference

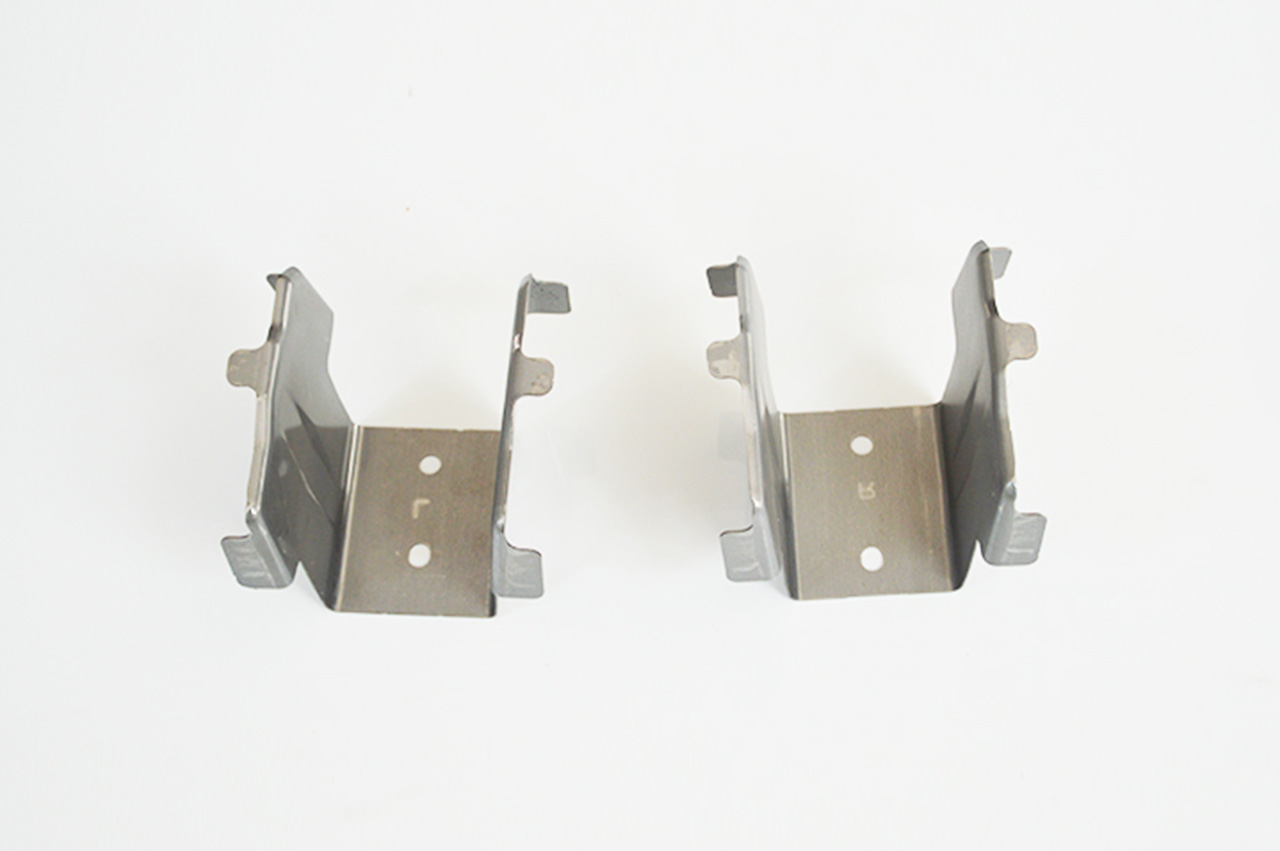

Part Name: Automotive Side Sill plate

Material Grade: Material RP783-980B

Material Size: Material size is 1.00mm x 770mm x 360mm

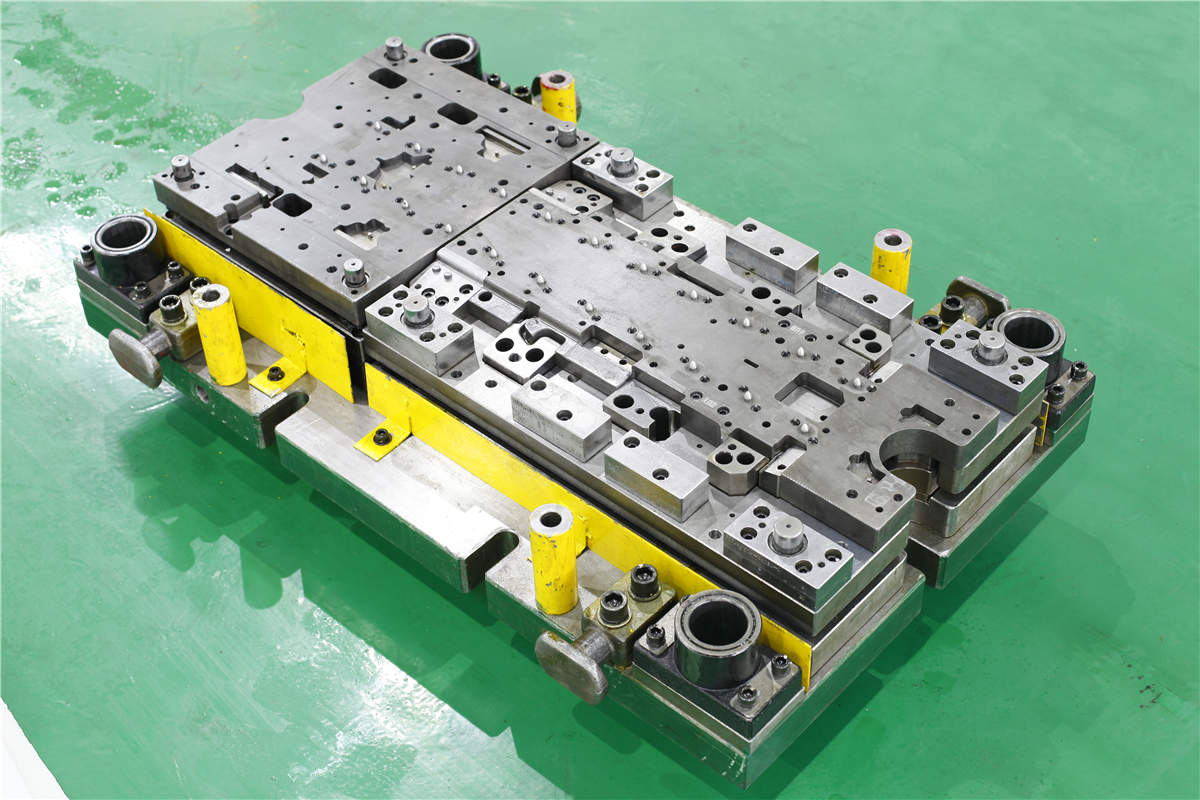

Process: Process stages 1000ton Progressive Blanking and 3000ton Transfer with 5 stages

Cavity: Tool cavity is Right and Left two parts out

Press Machine: 2000T, 1200T Mechanical

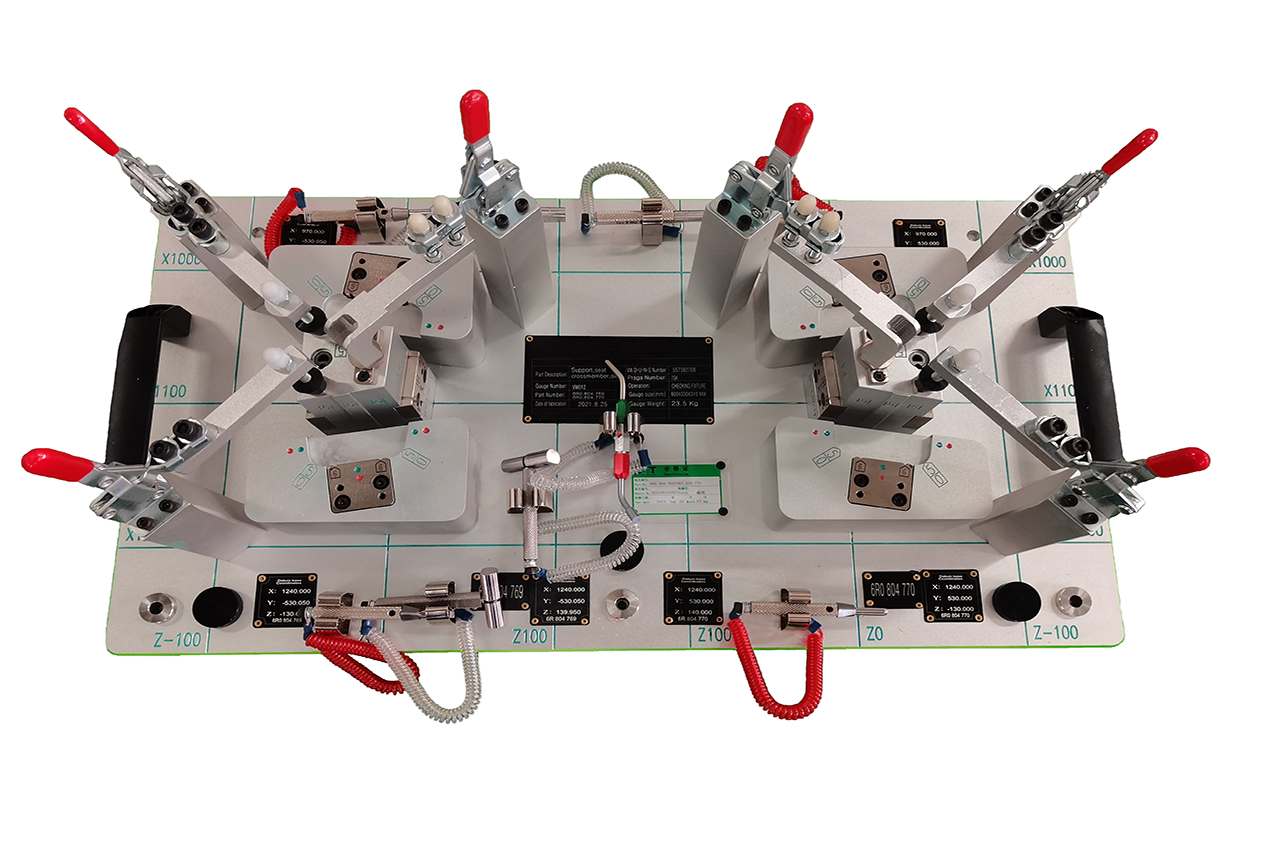

Inspection Tool: Checking Fixture and CMM

Lead Time: 5 months

Difference between progressive tool and transfer tool

Both progressive tool and transfer tool are all processes used to stamping parts, For producing large and high-volume parts, transfer tool is much more suitable, vice versa, progressive tool or compound tool. Depend on difference users, requirement, tolerance, design, product size, investment… and so on.

Progressive Tool

The stamping process is feeding a coil of metal through the stamping press

from beginning to end station, separating the individual finished parts from the first blanking to final operation.

Advantages of progressive tool:

High-efficient for production small parts

Scrap reduction

Cost reduction by combine stages together

Transfer Tool

The stamping process is each part work separately, the product transfer in the tool stations by gripper, mostly used for deep-draw, large size and high-volume products. The transfer tool can be a single tool or part of several tools lined up together. Transfer tool stamping is used to perform operations on the part free from the strip.

Advantages of transfer tool:

Single transfer tool in simple design

design change could be easily adopted

economical for complex product

How to choose the most suitable tool

-the design process complexity

-the type of production

-the speed of manufacture

-the size of the product

-the cost of the investment

-the requirement of product quality and tolerance

For simple small parts, progressive or transfer metal stamping tool may not be the best option, while for complex forming parts, one or the other is often the best choice. Both progressive and transfer tool stamping are widely used to manufacture automotive parts.

For this product, we choose transfer tool, because the high strength material grade, complex shape and customer requirement.

The best suitable stamping method for your product is depend on the application requirements. If you are hard to decide, please contact with us, we will evaluate and give you suggestions.

Product detail pictures:

Related Product Guide:

Our company sticks into the basic principle of "Quality is definitely the life of the business, and status may be the soul of it" for OEM manufacturer Metal Stamped Part - Automotive Side Sill plate – Meiln , The product will supply to all over the world, such as: Victoria, Plymouth, Mauritius, We'll continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.