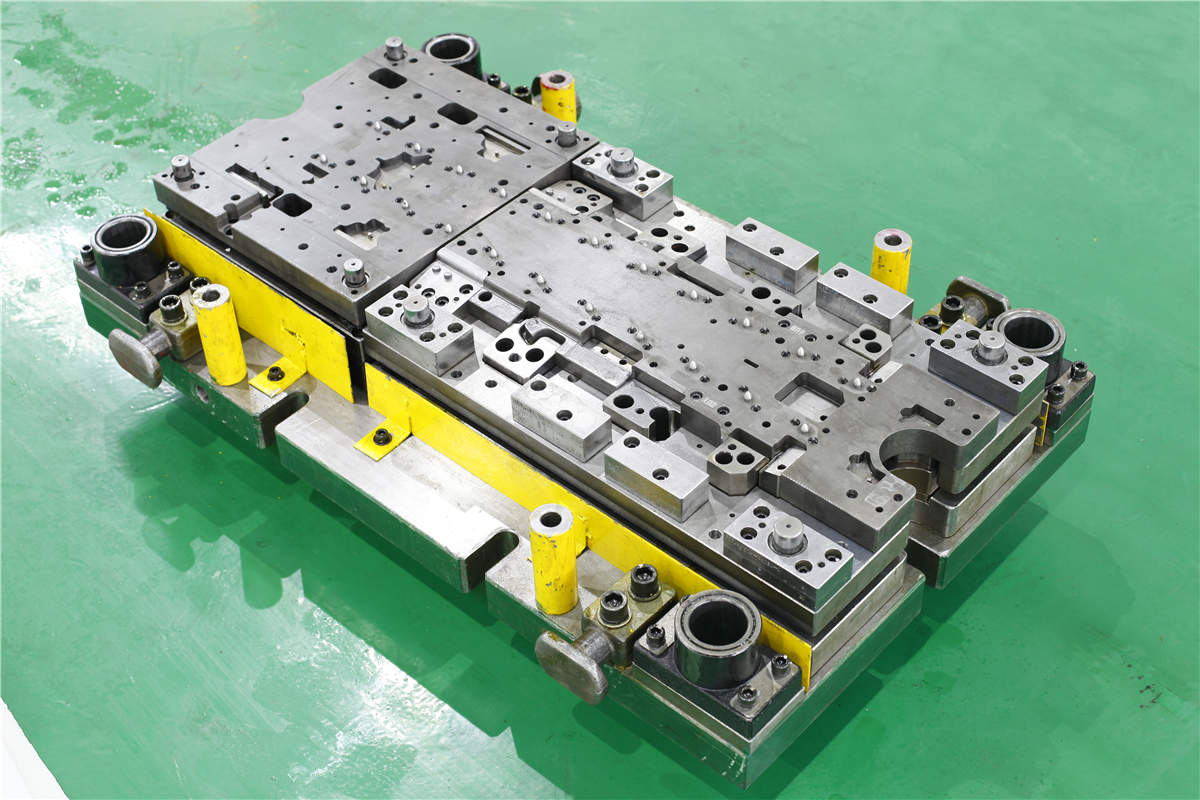

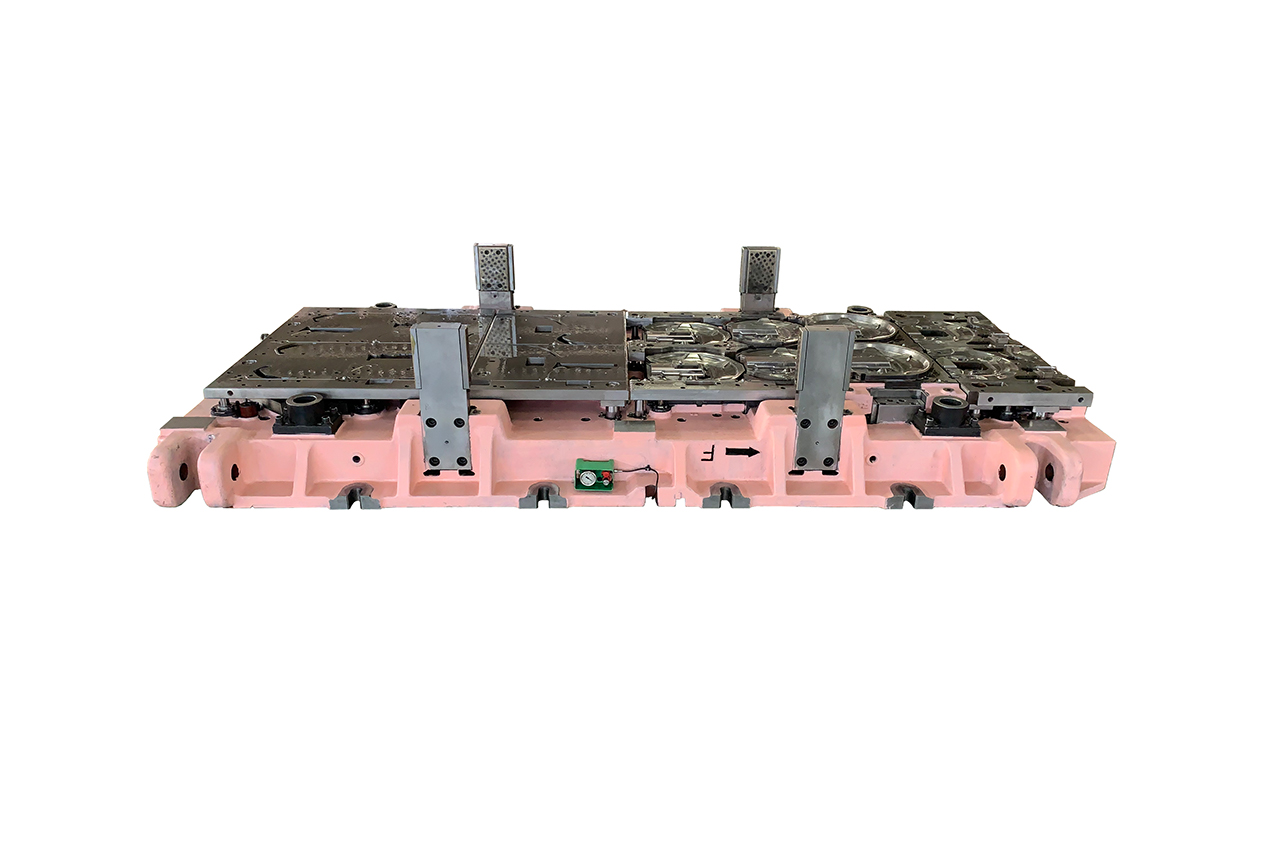

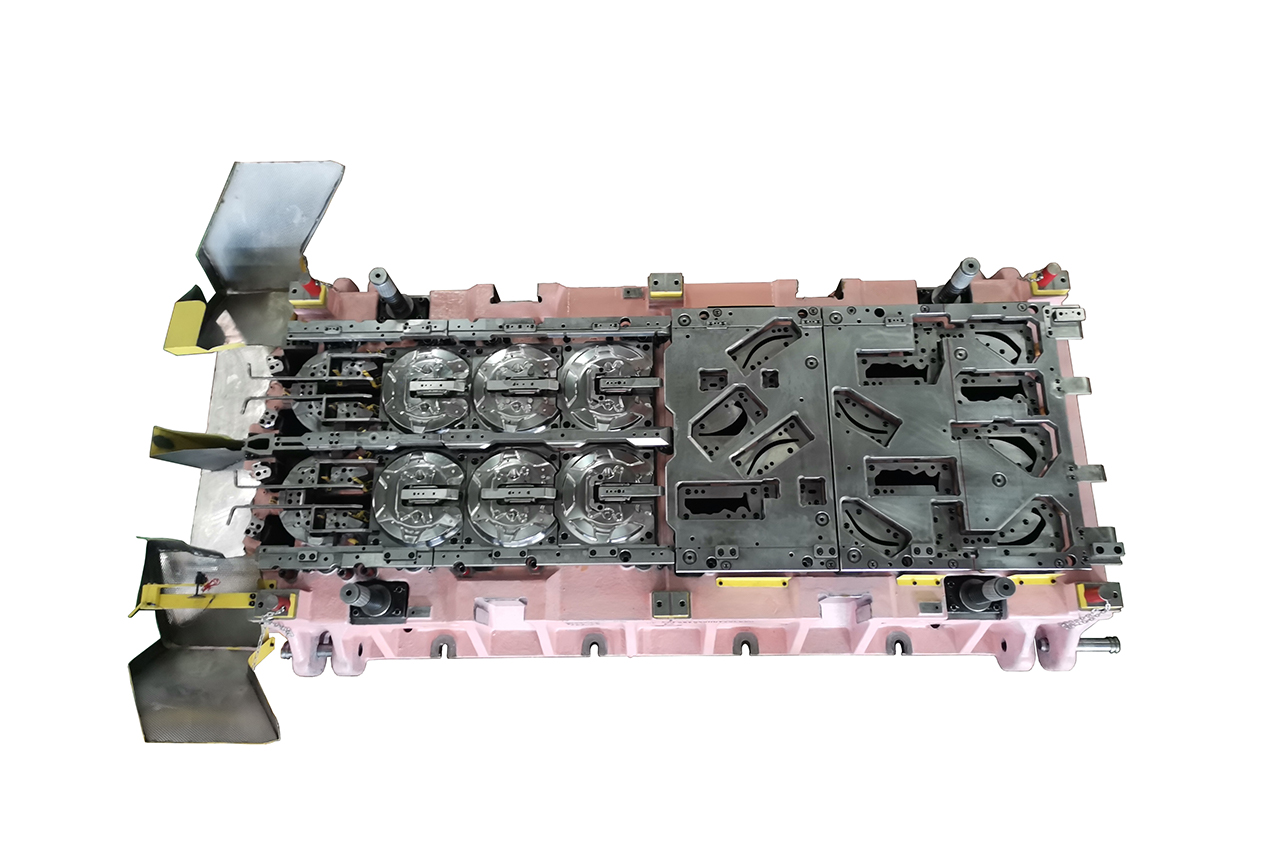

OEM Manufacturer Tool & Die Maker - Progression Tool – Meiln

OEM Manufacturer Tool & Die Maker - Progression Tool – Meiln Detail:

Tool type: Progressive tool

Process:

1.00mm x 872mm x 280mm – 800T PRG @ R and L Parts Out

0.8mm*840mm*348mm- 800T PRG @ x2 Parts Out

Stamping Part Material: GS 93033 ALUMINIUM AL5-11C-NP-UM O/H111

Tool Material Grade:

Upper and Lower die shoe & blank holder are used S50C material,

Forming and re-strike blank holder plates are used HMD5 material,

trim punch blank holder plates are used S50C material.

Steel Surface Treatment:

Forming punch: PVD

Forming punch:SKD11+TD

Standard Components:

Most of standard parts are sourced from MISUMI and PUNCH, gas spring are sourced from HYSON.

Complexity: Middle

◆Application: The tool applicated to automotive brake shield part

Lead Time: 4 months

Background:

Aluminum powder is easy to be created during mass production, resulting in scoring on the product surface, which is a common problem in mass production of aluminum parts.

We summarized the reasons why panel with scoring issue below.

1. The aluminum powder created in the die when form which caused high temperature sintering on the surface due to long move distance.

2. Insufficient lubrication and high friction caused scoring issue.

3. Forming gap is less than material thickness to form an extrusion condition, which is easy to cause scoring.

Countermeasure:

1. Use fine sandpaper or fine oil stone to remove the attachment and polishing.

2. Add a proper amount of special lubricating oil for aluminum parts in the die.

3. Increase forming gap tolerance. (lower die polishing)

We cleaned the die with fine sandpaper or fine oil stone during part production.

After treatment, we confirmed that the surface coating is not damaged.

Our service advantage:

1. 2 factories specializing in the production of tool.

2. strict quality inspection procedure

3. many workers with more than 10 years working experience

4. good after-sales service

5. Provide perfect forwarder service guidance

If you are interested in auto brake shield parts, please don’t hesitate to contact me, Meilin have much experience with these kinds of parts.

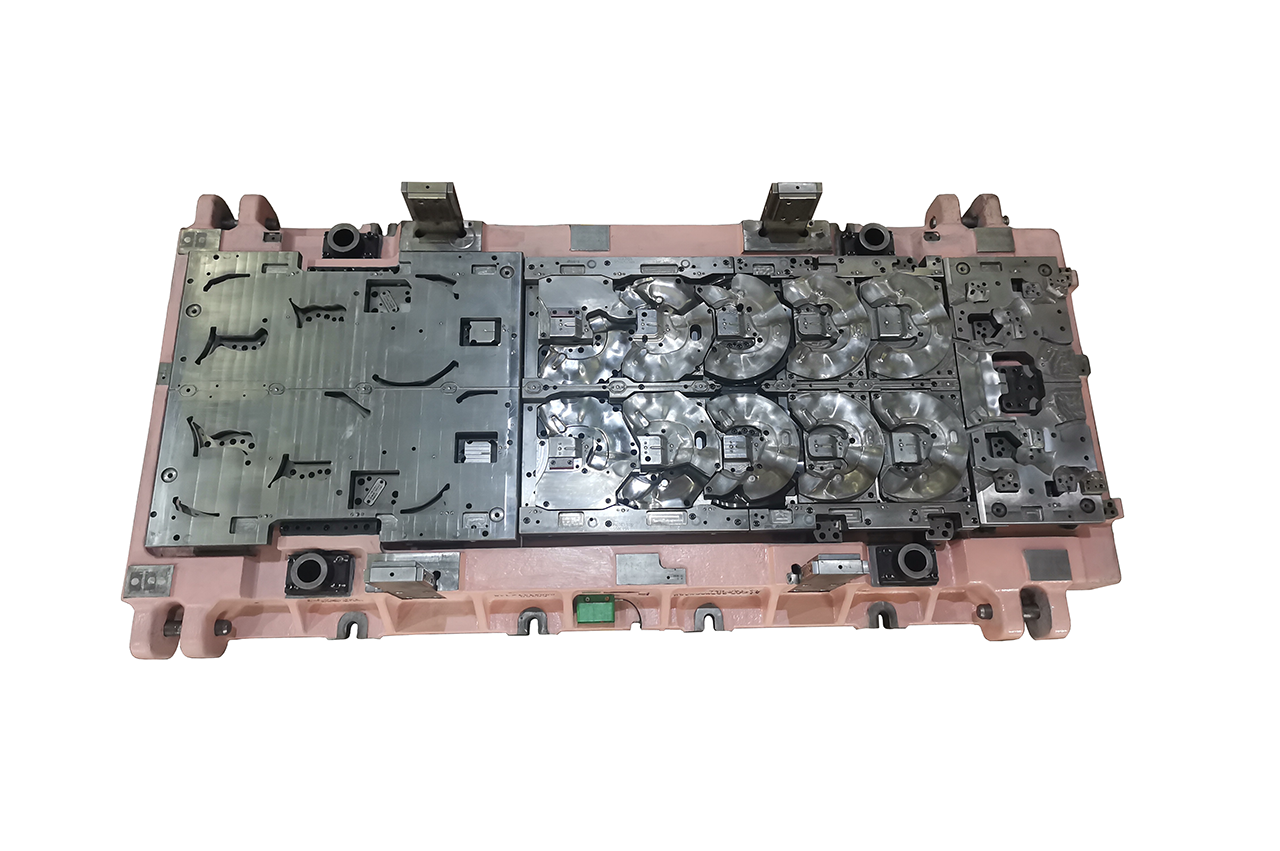

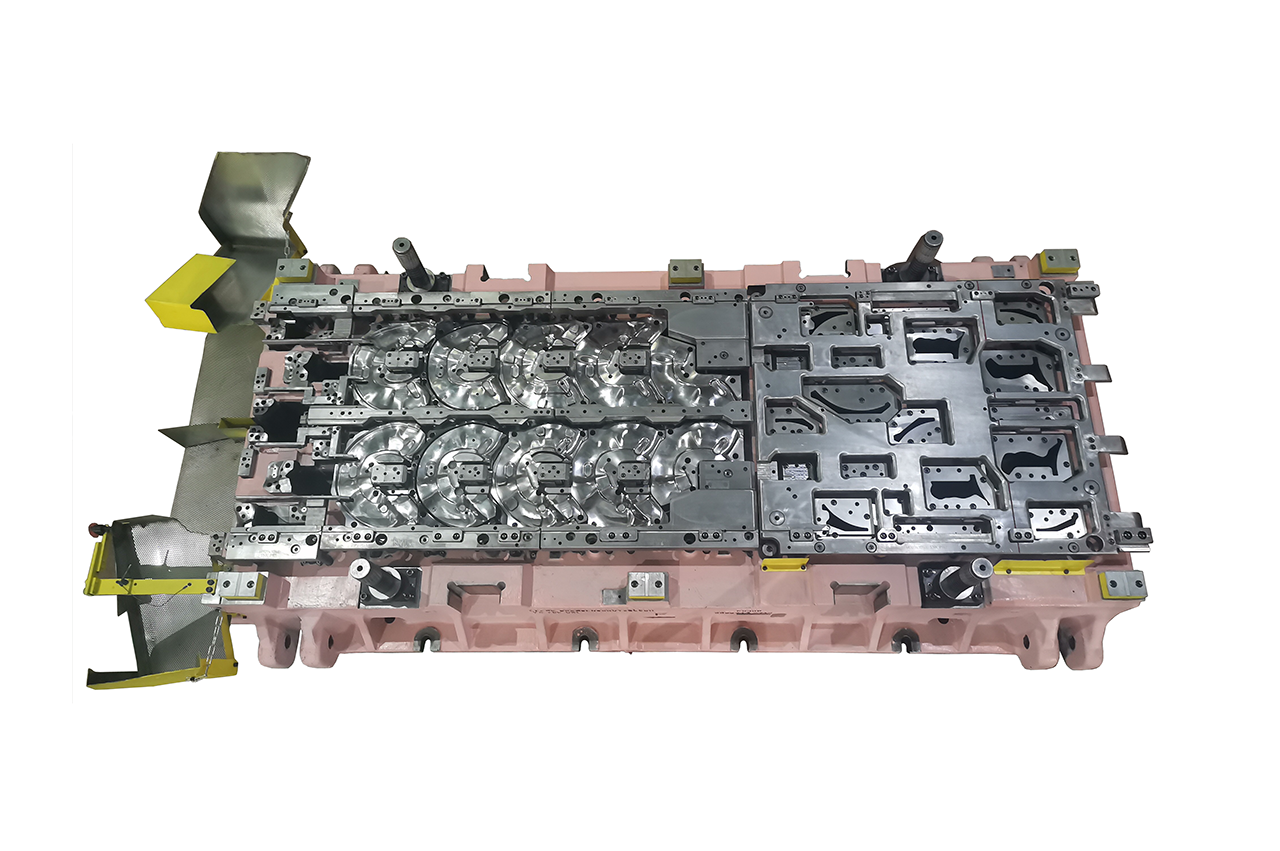

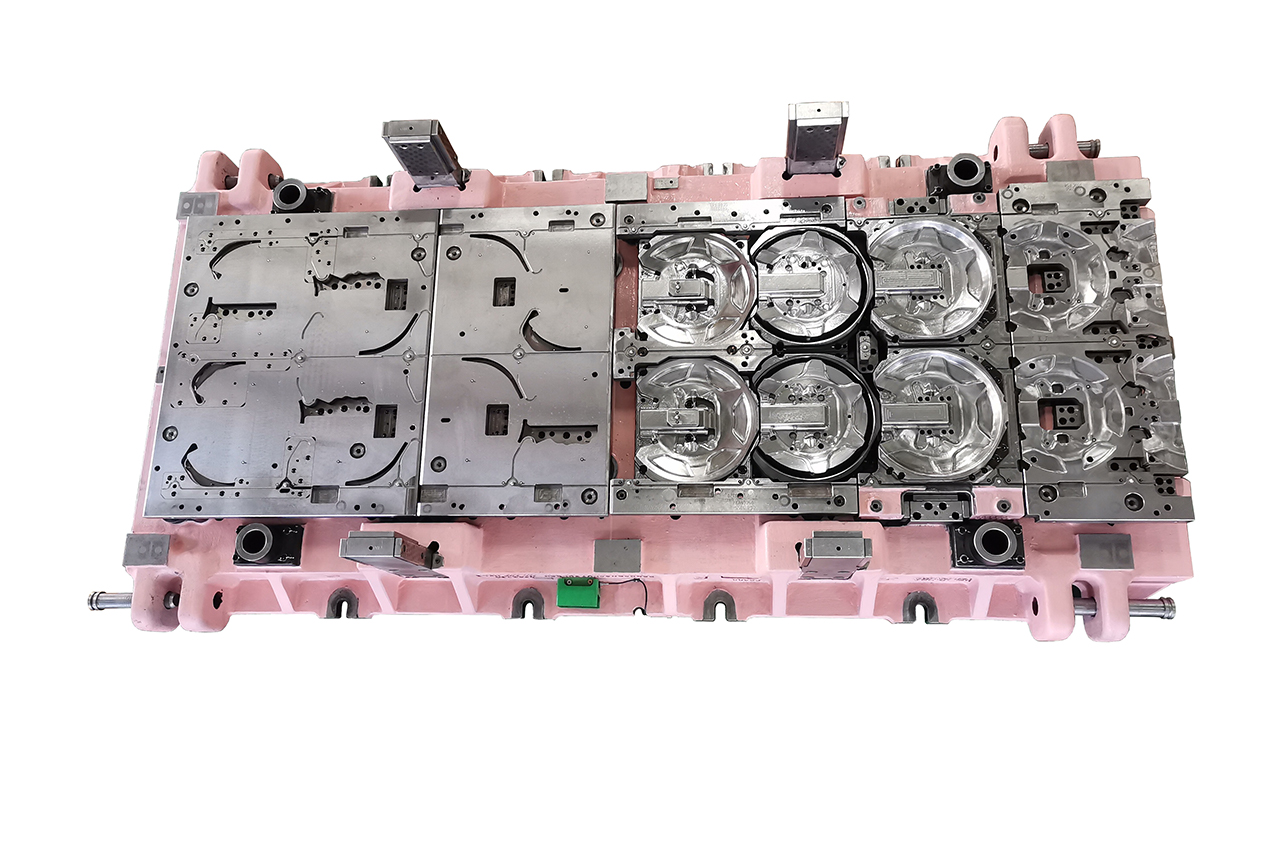

Product detail pictures:

.png)

.png)

-1.png)

Related Product Guide:

Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for OEM Manufacturer Tool & Die Maker - Progression Tool – Meiln , The product will supply to all over the world, such as: Latvia, Latvia, Macedonia, Insisting over the high-quality generation line management and prospects guide provider, we have made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!