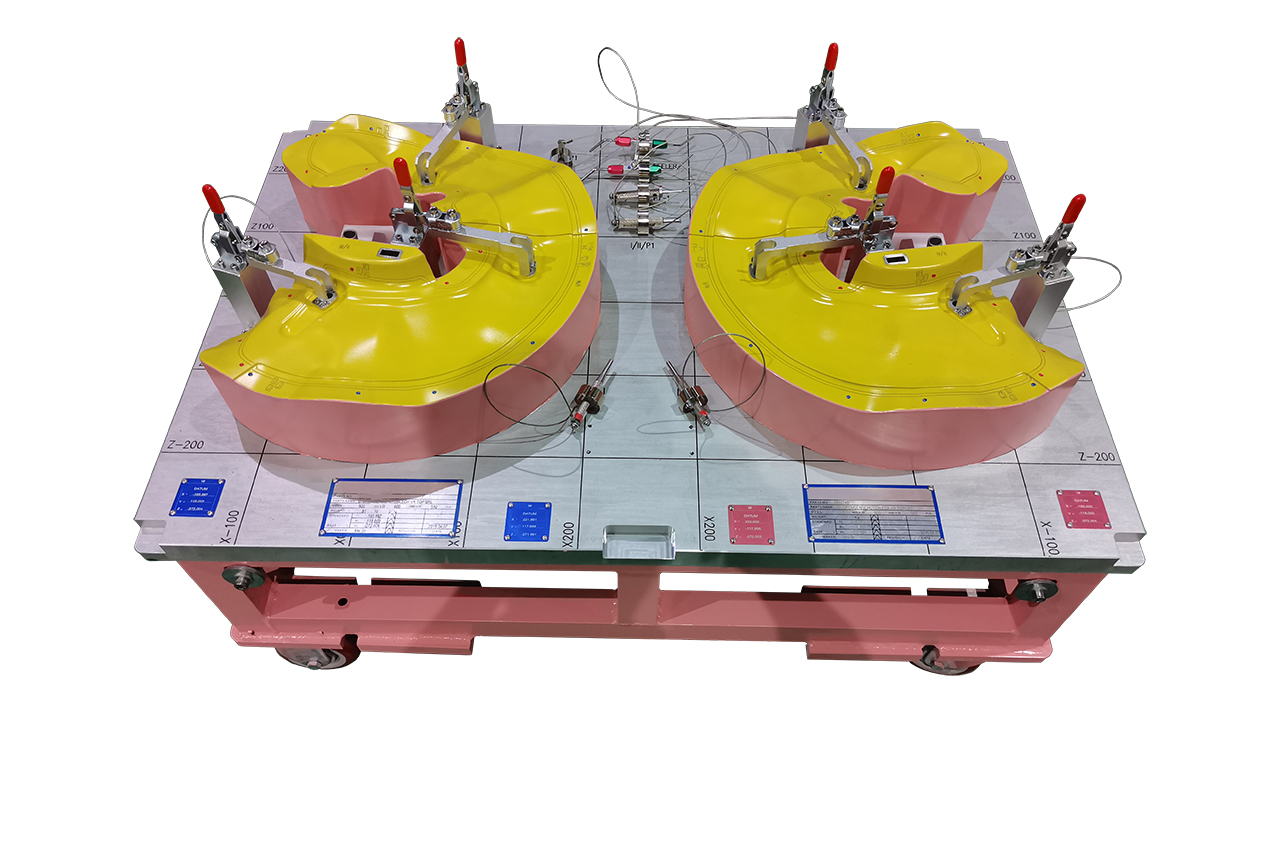

OEM Manufacturer Tool & Die Maker - Transfer – Meiln

OEM Manufacturer Tool & Die Maker - Transfer – Meiln Detail:

Tool type: Progression tool

Process: Progression 800T

Tool Size: 2700mm x 1860mm x 900mm

Tool Weight: Upper Weight 5358kg, Total Weight 11458kg

Tool Material Grade: Upper and Lower Die shoe & blank holder: S50C

Forming plate, trim punch & cutting edge: SKD11 HRC58-60

Stripper plate insert, some forming block: HMD-5

Steel Treatment: Forming block-Chroming

SKD11-Heat treatment

HMD-5-Surface hardening

Standard Components:

Main standard part are sourced from MISUMI, gas spring are.

Hole punch for aluminum part required with‘XANL’coating or use same / equivalent type of coating.

Stamping part material: AA6111 Aluminum

SPM: 53

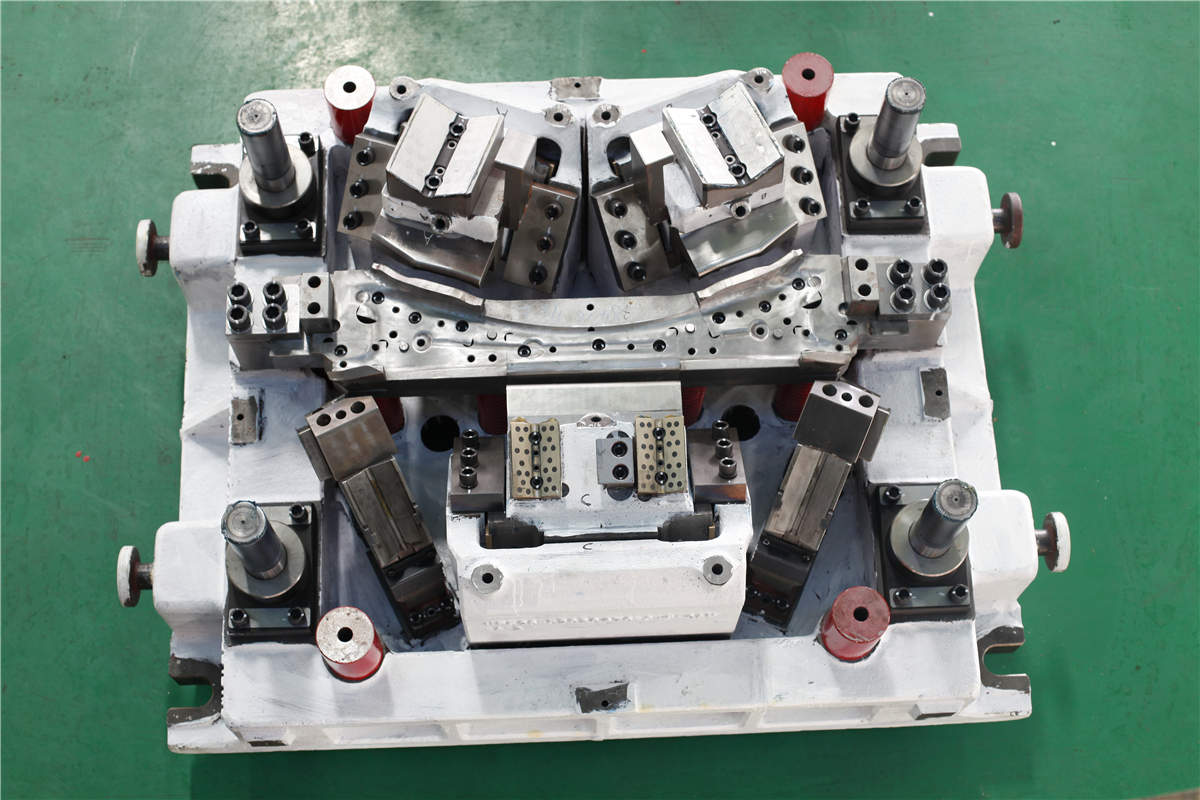

Cavity: R and L two part out

Complexity: Middle

◆Application: The tool applicated to automotive stamping part mass production.

Press Machine: 2000T hydraulic press, 1200T Mechanical

Lead Time: 4 months

◆Technical Challenge: Production issues of Aluminum part

Background:

Regarding production issues of Aluminum part, all pierce punches are picking up / scoring when undertaking a press run of over 300+ Blows, this is in-turn causing part quality issues with holes distorting from pull back and also burrs, even though aluminum is soft the main issue is with the coating on the actual aluminum coating, so due to this, for further aluminum part can coated punches be used for any aluminum part to improve this issue.

Advantage:

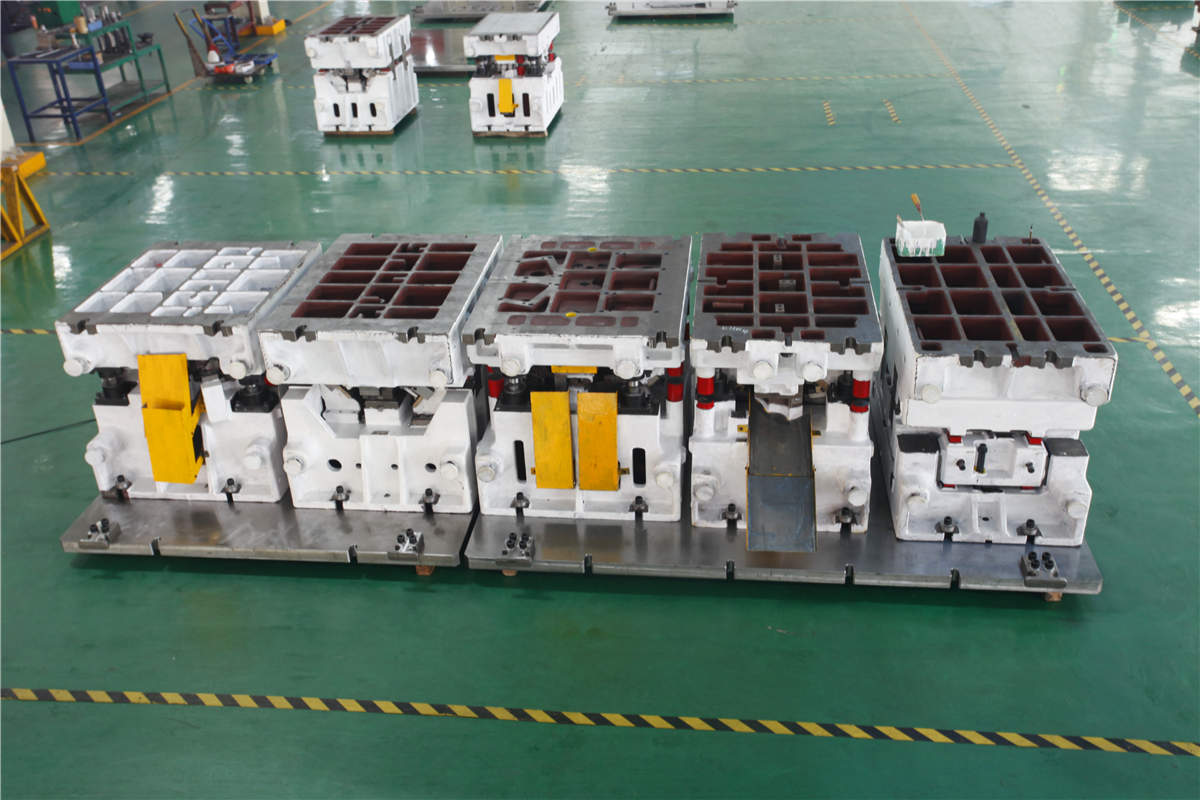

We have much rich experience with large size progression tool as well as aluminum part, which length is up to 4.2 meter.

One-stop service: Dies Simulation & designing, manufacturing, tryout, and producing stamping parts all can be done in our plant.

Quality System: ISO9001-2015 System certificate, for the following activities

Manufacture and Sale of mould, Checking fixture and parts

If you are interested in progression tool or have any other questions, please don’t hesitate to contact me, and we will be pleased to reply you.

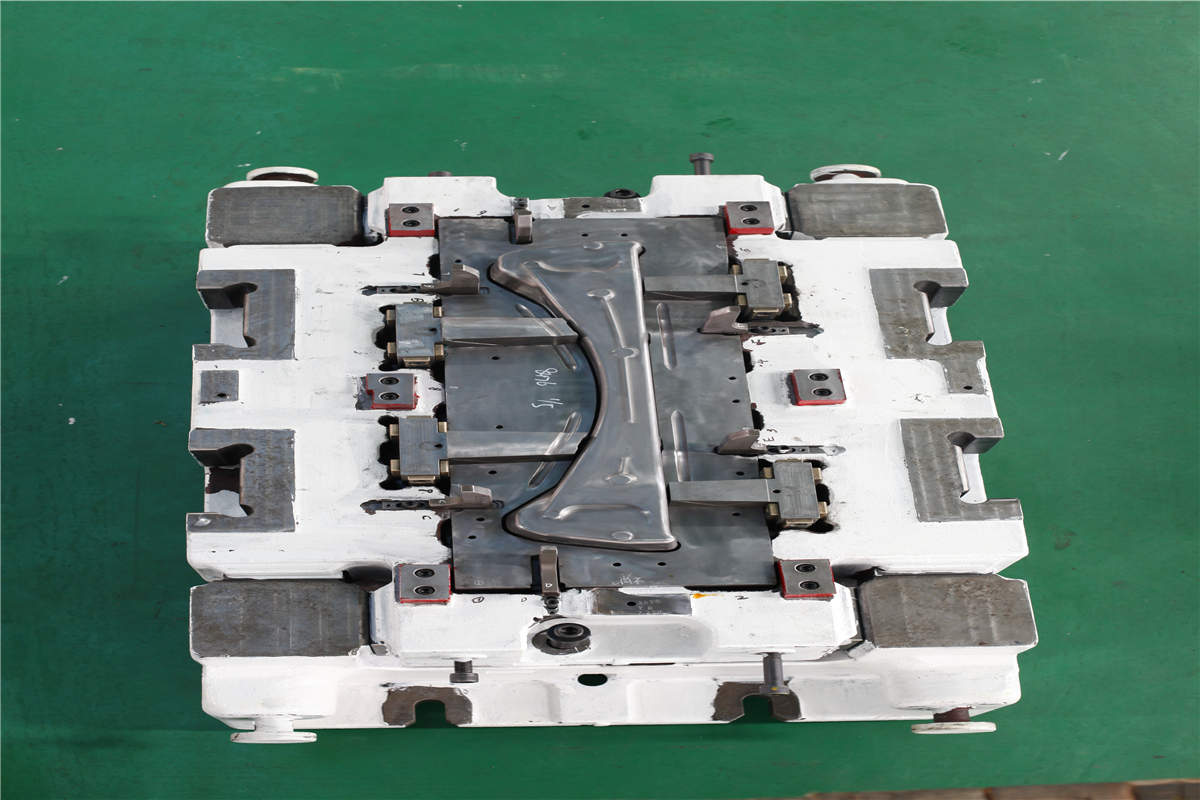

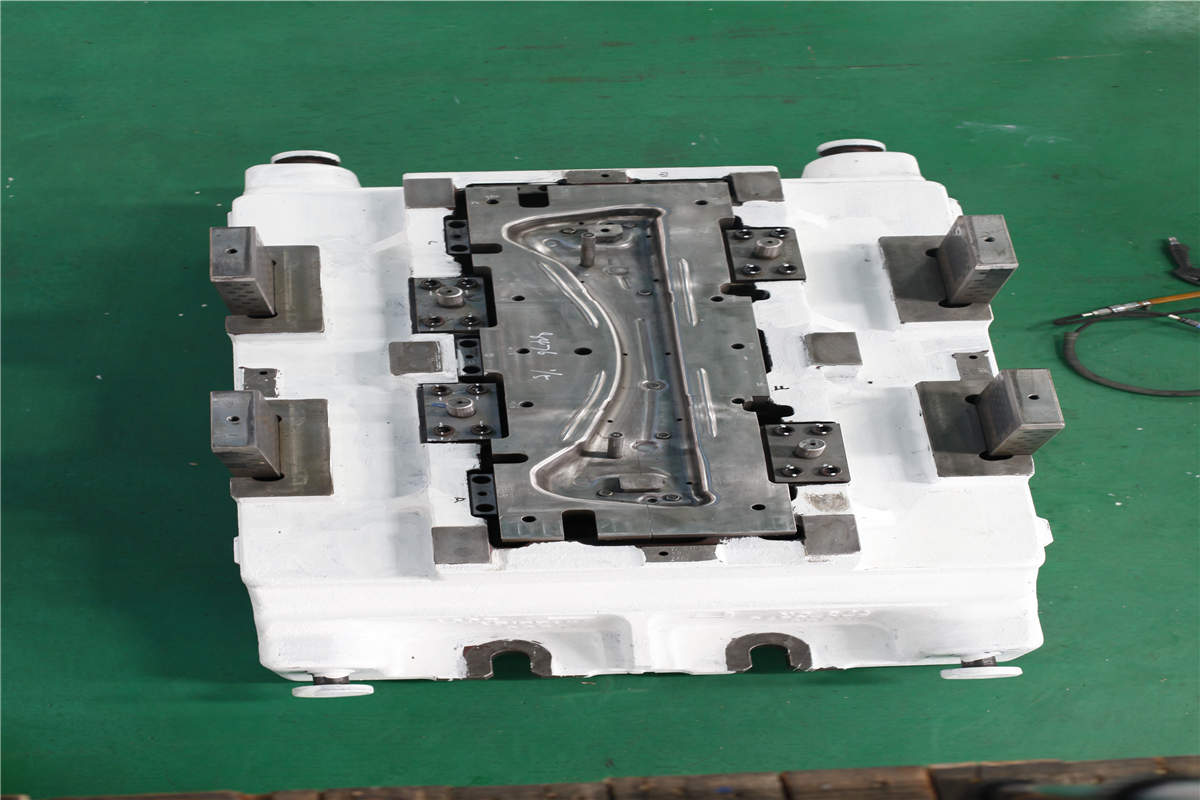

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for OEM Manufacturer Tool & Die Maker - Transfer – Meiln , The product will supply to all over the world, such as: Hamburg, Manila, Algeria, Each customer's satisfactory is our goal. We are looking for long-term cooperation with each customer. To meet this, we keep up our quality and provide extraordinary customer service. Welcome to our company, we are expecting to cooperate with you.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!

.png)