One of Hottest for Stamping Automotive Parts - Automotive Brace Sill Product – Meiln

One of Hottest for Stamping Automotive Parts - Automotive Brace Sill Product – Meiln Detail:

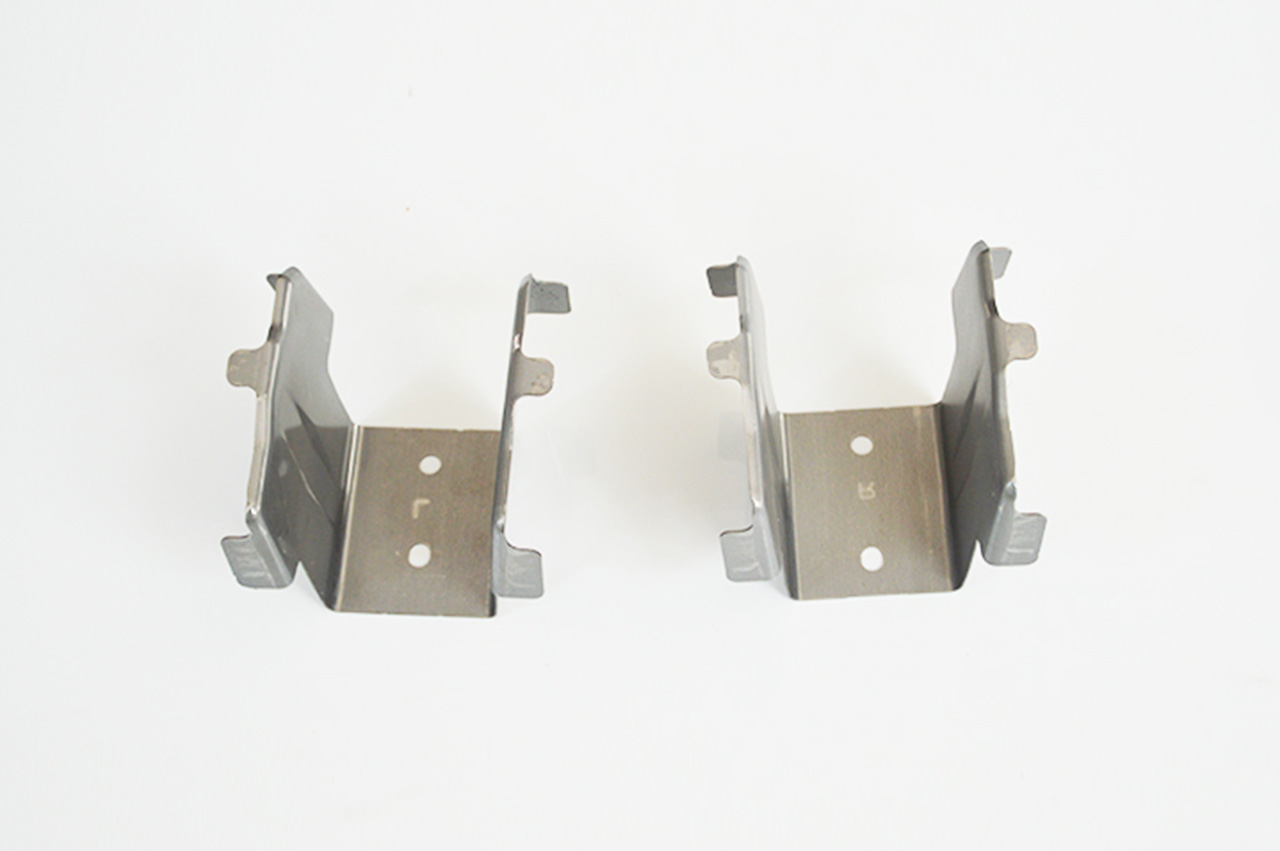

Part Name: Automotive Brace Sill Product

Material Grade: Material RP783-980B

Steel Level: Deep drawing quality

Strength Level: High Strength Steel (HSS), Ultra Strength Steel (USS)

Thickness Range: 0.8mm to 4.0mm

Process Method: Cold Rolled Coil

Material Origin: Japan

Material Size: Material size is 1.2mm x744mm x 196mm

Process: 1000ton Progressive

Part Cavity: Tool cavity right and left two parts Out

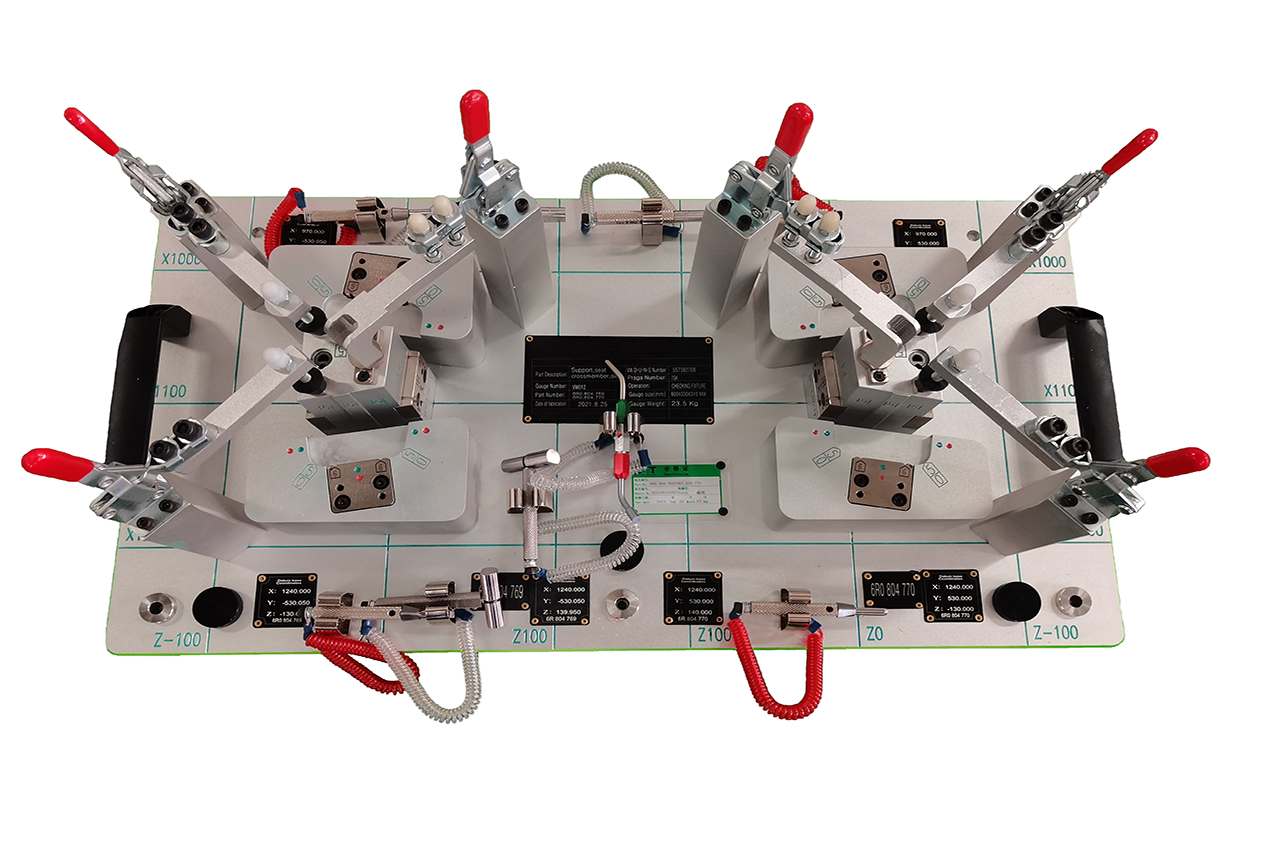

Inspection Tool: Checking fixture, CMM and Blue Scanner

Place of Origin: Huizhou, Guangdong, China

Lead Time: 4.5 months

Production Introduction:

This is common high strength steel product, spring back concerns for the side walls. As the product shape, the two sides are easily open to each angle. The key problem is to deal with spring back.

In the initial forming simulation, the report not showed serious bad results. And the process not complicated, we have confidence in making the product in good quality in a reasonable lead time.

Based on our experience, for right and left cavity parts, sometime, the two parts in different status not identical. Then further die tuning works are slightly changed.

After carefully process discussion and analysis, machining goes smoothly, everything goes in order, the first die off part nearly at T2 level, better than T1 quality targets. Both the sample and die have been measured and scanned, every point that in NG condition have been checked, even forming steels, inserts surface. Heat-treatment and surface coating.

Experience and Achievements in making high strength automotive parts

Since the year of 2010, more than 10 year experiences in producing auto high strength products.

From the simple drawing, forming product to big complex automotive steel parts.

Original one cavity to common right and left part out.

Transfer die to Progressive die.

Only focus on making automotive metal die and tools.

Good feedback from customers, not only China domestic but also overseas.

Please contact with us without hesitate if you have any inquiry.

Product detail pictures:

Related Product Guide:

With our great management, potent technical capability and strict excellent handle procedure, we continue on to provide our customers with reputable top quality, reasonable selling prices and great providers. We purpose at becoming amongst your most trusted partners and earning your satisfaction for One of Hottest for Stamping Automotive Parts - Automotive Brace Sill Product – Meiln , The product will supply to all over the world, such as: Spain, Georgia, Myanmar, Now we are sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We are ready to share win-win corporation.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.