One of Hottest for Stamping Automotive Parts - Automotive Side Connecting plate – Meiln

One of Hottest for Stamping Automotive Parts - Automotive Side Connecting plate – Meiln Detail:

Brief Description: Hole Distortion Countermeasure

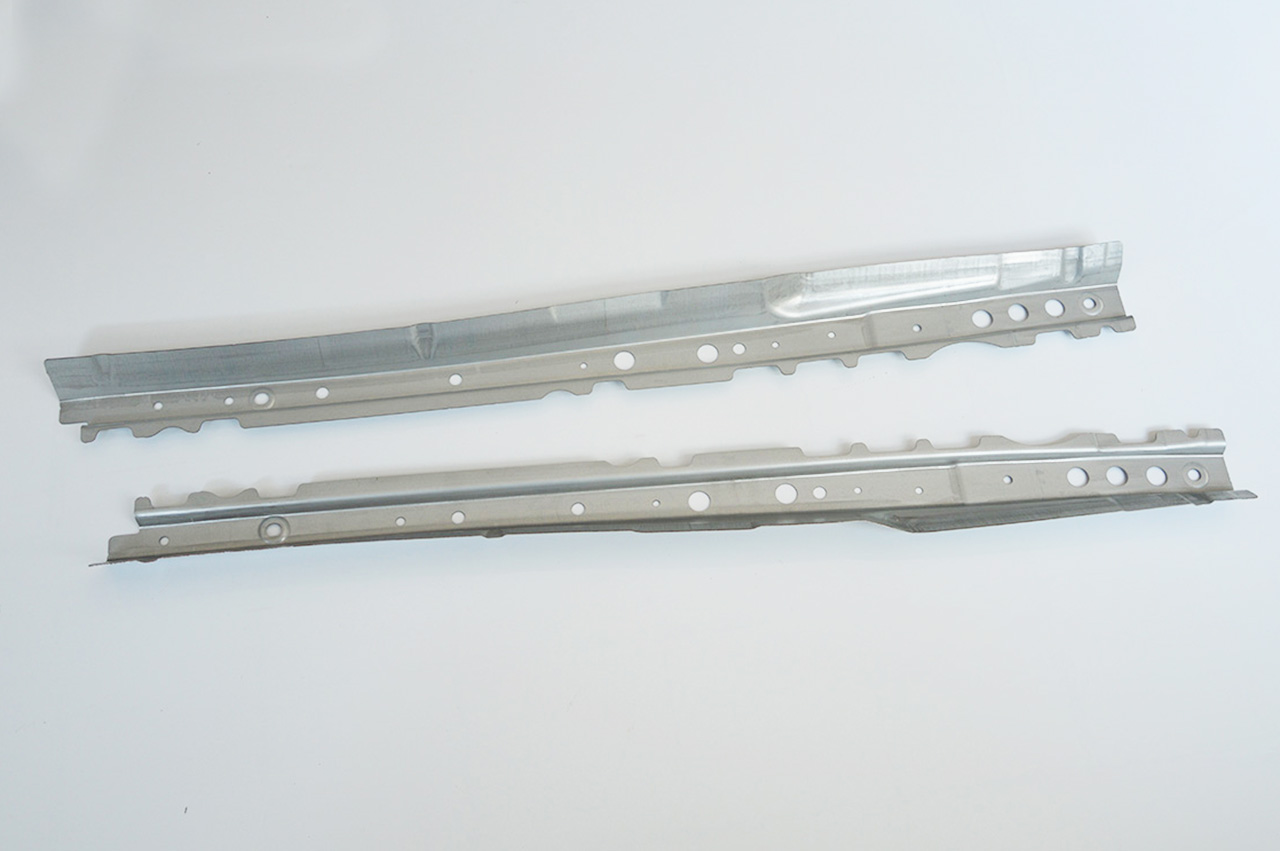

Part Name: Automotive Side Connecting plate

Material Grade: Material CR380LA -ZM35/35-U

Material Size: Material size is 1.20mm x 1038mm x 265mm

Process: Process stages 2500T Transfer with 5 stages

Cavity: Tool cavity is Right and Left two parts out

Press Machine: 2000T, 1200T Mechanical

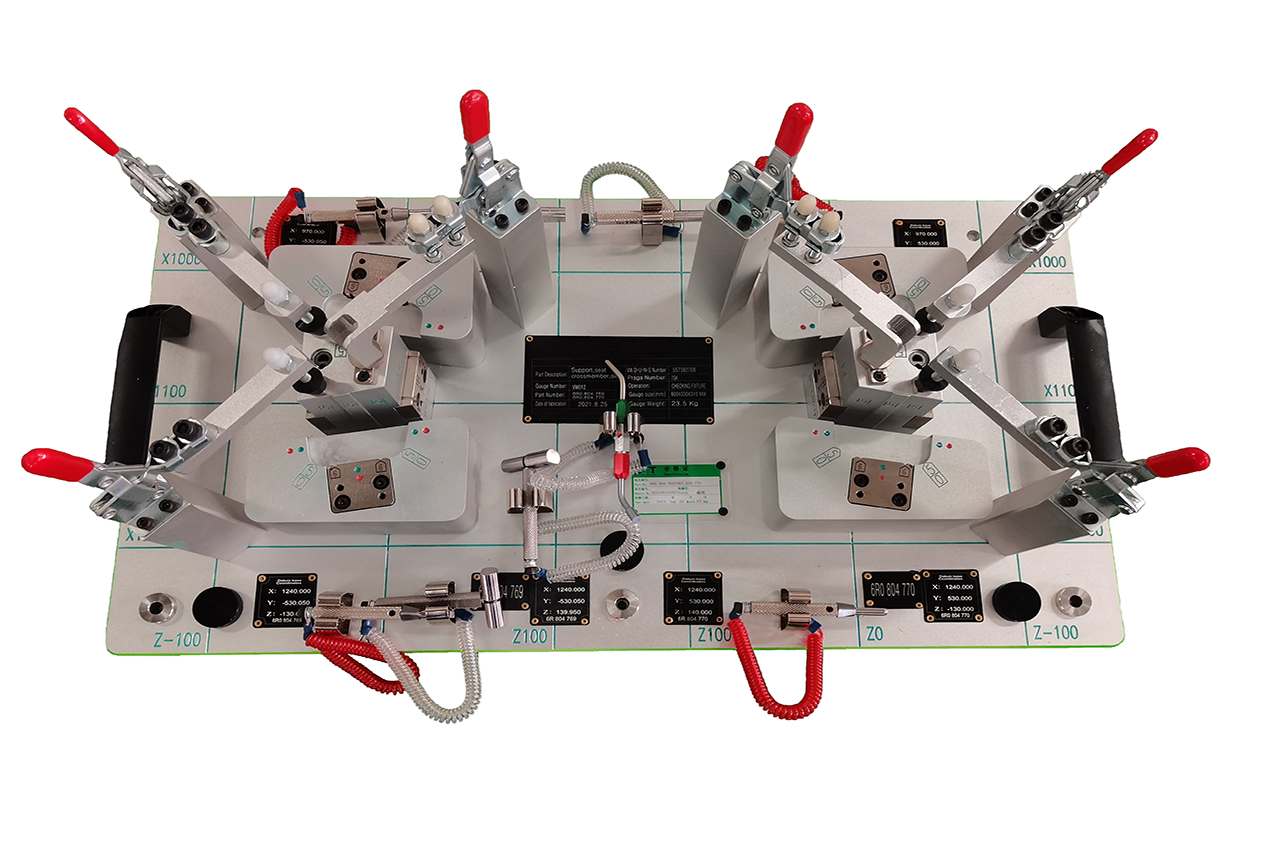

Inspection Tool: Checking Fixture, Blue Scanner

Lead Time: 4 months

Technical Concerns: Hole Distortion

As the product in slim shape with a lot of holes, which is distortion easily.

Some holes could be achieved in the blanking stations, however, most of the holes have to be finished in the separate pierce stations.

How to avoid hole distortion in automotive metal parts?

The hole finish by pierce and cam-pierce process with a punch in the die.

the full length of the bend to be pressed into the die by a punch. The resulting bend smoothly and accurately matches the bend radius of the punch and die. A hole located near the punch is likely to be distorted and warped during the bending process.

Whether a hole is in the risk of distortion or not? It depends on the bend radius, method, and product size.

If the hole and bend close, add a relief will reduce the possibility of the hole being distorted.

Also considering punch coating, especially for aluminum materials. Aluminum product is common to see the hole distortion concerns. Punch in different coating will affect hole quality. For small quantity die try out, it seems OK. While in the mass production with high SPM, it will show significant works.

In order to keep hole in good quality, hole size accuracy, hole surrounding surface smoothly, the process should be considered carefully.

To solve the hole piercing concerns, we could share with you much more experiences if you have interest. Please contact with us.

Product detail pictures:

Related Product Guide:

Sticking to the perception of "Creating products of top of the range and earning mates with people today from all over the world", we constantly put the desire of consumers in the first place for One of Hottest for Stamping Automotive Parts - Automotive Side Connecting plate – Meiln , The product will supply to all over the world, such as: Zambia, Jamaica, Morocco, With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!