Online Exporter Auto Parts Checking Fixture - Reinforcement Assembly Front Side Rear Part – Meiln

Online Exporter Auto Parts Checking Fixture - Reinforcement Assembly Front Side Rear Part – Meiln Detail:

Part Name:

Reinforcement Assembly Front Side Rear RH/LH

Material Grade: DP600 + Z100

Material Size: 1.40mm x 1075mm x 610mm

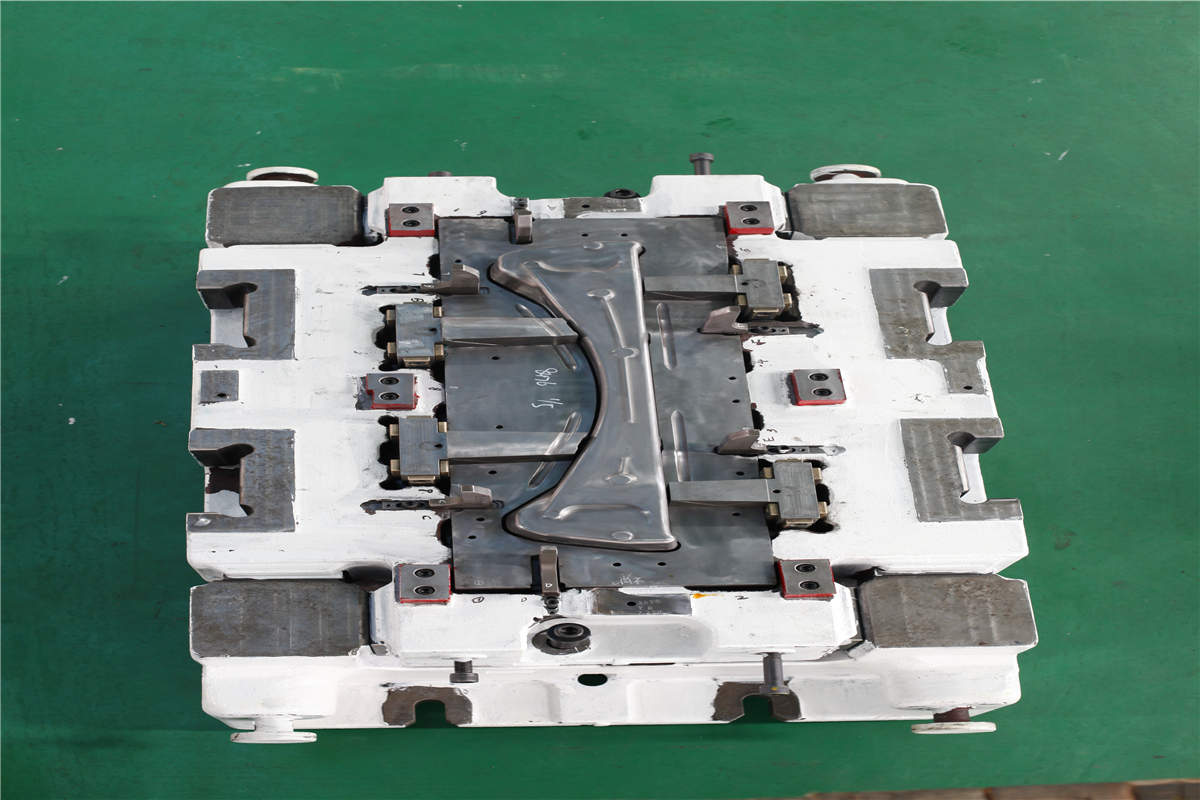

Stage Process: 600T PRG Blank & x 5 Stage 2500T TRF

Cavity: R and L parts out

Press Machine: 1200T Mechanical, 2000T press

Feeder Machine: used for COIL trial material

Inspection Tool: Checking fixture, Laser scan, CMM

Lead Time: 5 months

Technical Key Point:

Part quality of high strength plate stamping part

Background:

This part is high strength plate. Compared with ordinary metal plate, it has properties of high yield strength, bottom section shrinkage rate. Using high strength plate stamping, the common problem encountered is after forming, the part produced spring back, deformation, wrinkle, and it is not easy to solve. The secondary problems affecting part quality are stamping die life and process stability.

In order to avoid great spring in the actual production of the part, after the drawing forming process to do a good job of digital modeling, it is necessary to carry out CAE analysis, and according to the results of analysis, determine the size of the spring back trend of parts, and then compensate in the data, and the compensated digital modeling as the processing basis.

Although the computer technology is very advanced at present, the objective conditions of CAE analysis by computer and the actual environment of mold work cannot be exactly the same, so it is necessary to recompensate in production and die adjust according to the actual situation of adjustment.

During the tool adjust, 4 Radius of the part shown split and thinning issues, and the spring back problem led to uneven surface, surface deformation, and wrinkle. According to these problems, our designer modified the 3D modeling of the part, make surface compensation to improve the flatness problem, and then modified the trim to improve the Radius split problem.

Conclusion:

Through the study of quality problems such as spring back, deformation and split of high strength plate, effective measures are taken in the die tuning process, and finally product the stable and qualified part. It not only meets the requirements of customers to shorten the production cycle and improve part quality, but also accumulates valuable experience for our factory to develop high strength sheet metal die, which makes our overall stamping technology level rise to a new level.

Product detail pictures:

Related Product Guide:

Excellent 1st,and Client Supreme is our guideline to deliver the ideal provider to our prospects.Nowadays, we have been seeking our best to become certainly one of the most effective exporters in our discipline to meet shoppers more require for Online Exporter Auto Parts Checking Fixture - Reinforcement Assembly Front Side Rear Part – Meiln , The product will supply to all over the world, such as: Poland, Poland, Namibia, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!