Professional China Cnc Mechanical Inspection Fixture And Jig Part - Member Front Side Upper Part – Meiln

Professional China Cnc Mechanical Inspection Fixture And Jig Part - Member Front Side Upper Part – Meiln Detail:

Part Name:

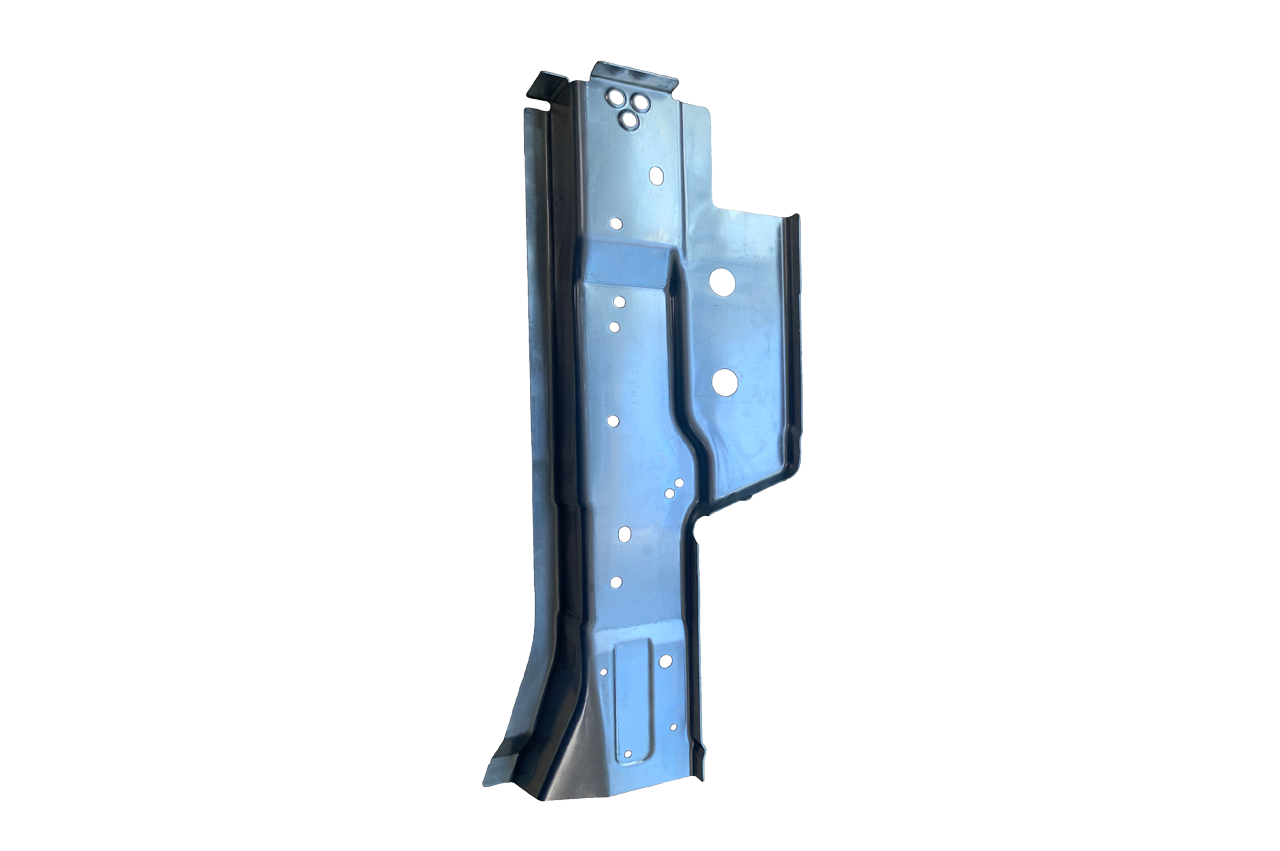

Member Front Side Upper RH/LH

Material Grade: AC300

Material Size: 2.50mm x 1030mm x 1012mm

Stage Process: 600T PRG Blank & x 4 Stage 2500T TRF

Cavity: R and L parts out

Press Machine: 1200T Mechanical, 2000T press

Feeder Machine: used for COIL trial material

Inspection Tool: Checking fixture, Laser scan, CMM

Lead Time: 6 months

Technical Key Point:

Forming simulation helps to improve Aluminum Part quality with split and thinning issues

Background:

The analysis of split, spring back, wrinkle, spring back compensation and tensile thinning of automobile body-in-white stamping parts is an important source of stamping die process design data. Spring back, thinning, wrinkling and split are common defects in the production process of stamping parts, especially when the drawing depth of stamping parts and the size of blank holder force of press are out of control. Therefore, tool design and simulation are particularly important before stamping.

This part looks quite long and big, which will likely cause many quality issues, such as split, thinning, deformation and wrinkle. Through product stamping forming simulation application process analysis, not only can accurately calculate the sheet material flow and material distribution thinning data, but also can judge the split and thinning of product stamping parts, reduce scrap rate in production.

The formability analysis of traditional parts can only rely on the experience and evaluation of designers to judge the feasibility of product stamping die design and production, resulting in many problems in the subsequent development process. Split and thinning can be eliminated by optimizing the ECR design by changing the profile Angle of the product. New energy vehicle stamping die design, CAE stamping formability analysis is very important to determine the process plan, directly related to the follow-up mold development, is also the key to shorten the mold development cycle.

Conclusion:

It is very important to use simulation software for complex, big, Aluminum or high tensile part, which can analyze the possible risks of the part quality improve so as to find ways to improve part quality issues.

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Professional China Cnc Mechanical Inspection Fixture And Jig Part - Member Front Side Upper Part – Meiln , The product will supply to all over the world, such as: Poland, Niger, Kuwait, Our products have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll provide the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!