Short Lead Time for Casting Aluminum Checking Fixture - Fixture resin – Meiln

Short Lead Time for Casting Aluminum Checking Fixture - Fixture resin – Meiln Detail:

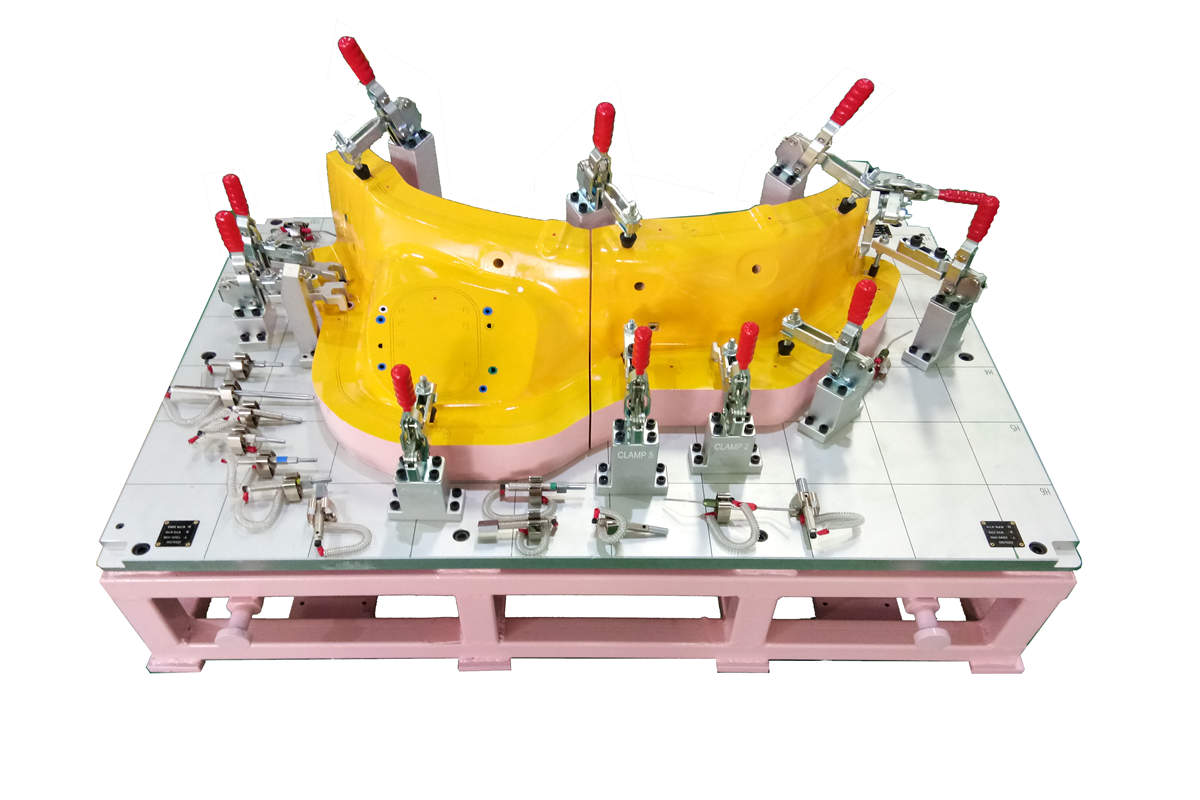

Part Name: ZB GEPAECKRAUMWANNE MITTE

Cavity: one part out

Material: Base Plate is made of Aluminum and Main body is made of Resin

Treatment: Metal area =Anodised

Resin area =painted

Lifting Method of Fixture: trolley

Application: The fixture applicated to automotive stamping part measurement

Lead Time: one month

Background

Regarding the lifting method of fixture, we consider all fixtures require an easy method of lifting, whether this by hand and adding handles or for larger fixtures ensuring that they are on a trolley to ensure easy movement. Some fixtures which are overweight and due to the size they can’t be manually lifted. These items require lifting aids to be added to make users friendly.

As to fixture material, this fixture is made of resin, which is not easy to deform even under the influence of environment, and is conducive to dimensional stability.

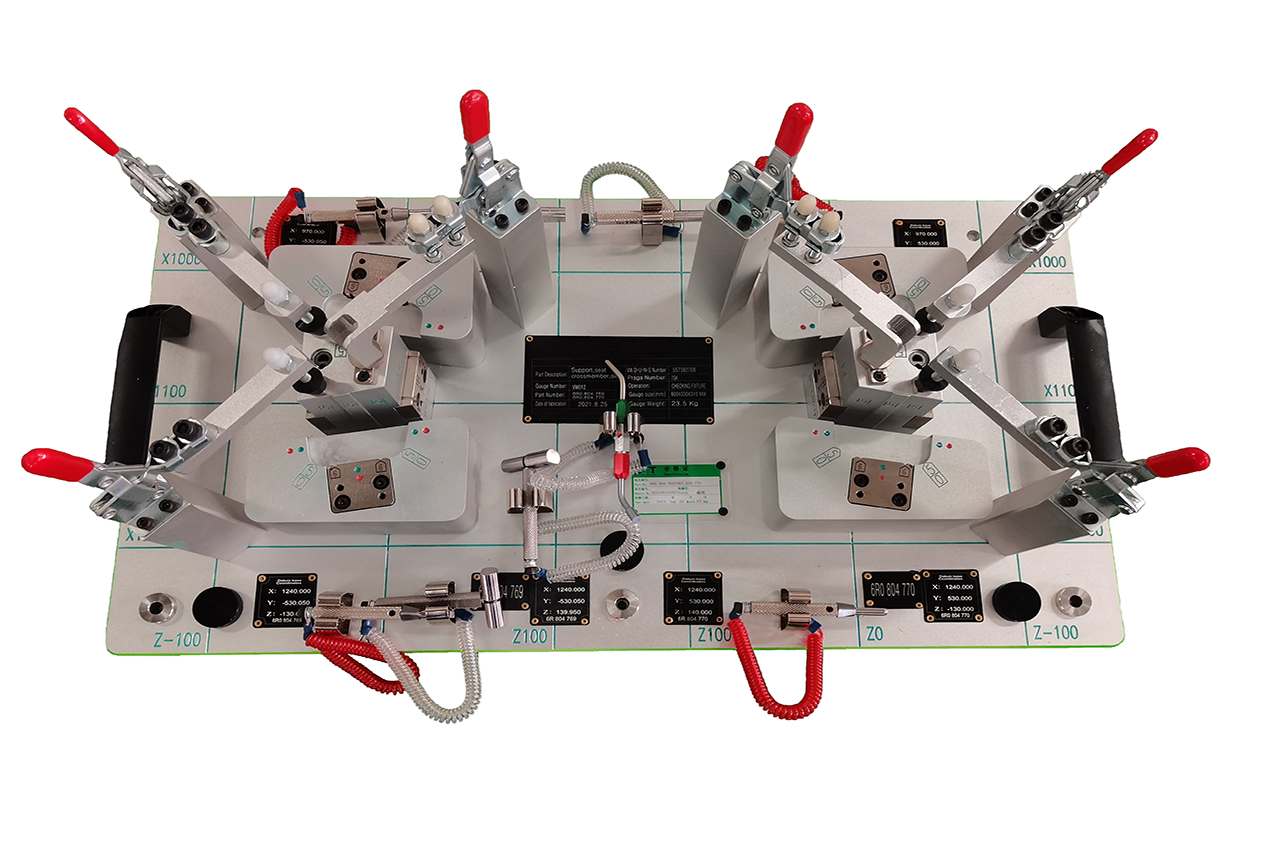

There are three alignment plates sat on fixture corners, which have come in with correct ‘X,Y,Z’ co-ordinates making it easy to accurately measure the part in car line. These plates are meant to be the datum of the fixture, these being correct means correct measurements could be sent to customer.

Function of the fixture

1. Inspect the hole position and hole size tolerance of the part.

2. Inspect the relating surface profile of the part.

3. Inspect the relating trim of the part.

4. Inspect the other relating dimensions of the part.

Fixture Maintenance

1. Apply for anti-rusty oil on the locating pins after using each time

2. Put the gauge in a specified area and cover the dust cover.

3. Not allowed for any heavy things to hit or touch or extrusion. Otherwise, the gauge precision will be affected.

4. Not allowed to disassemble the gauge. Otherwise, will be badly affected with the gauge precision.

If you have interest or want to know more about Resin checking fixture, please do not hesitate to contact us. We are pleased to discuss with you.

Product detail pictures:

Related Product Guide:

Our firm sticks to the basic principle of "Quality is the life of your company, and status will be the soul of it" for Short Lead Time for Casting Aluminum Checking Fixture - Fixture resin – Meiln , The product will supply to all over the world, such as: moldova, Swansea, New Orleans, Taking the core concept of "to be the Responsible". We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

.png)