Factory Cheap Cnc Checking Fixture Components Metal Stamping Parts - Automotive Cross Member Part – Meiln

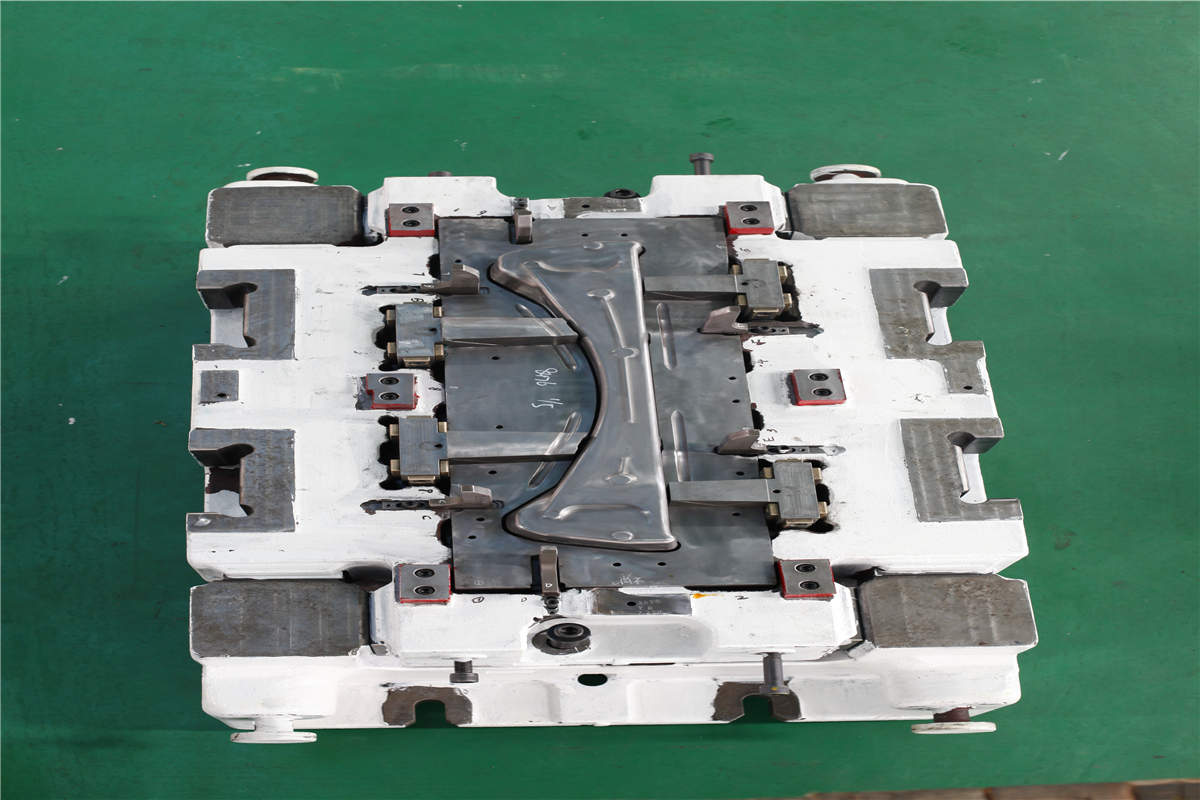

Factory Cheap Cnc Checking Fixture Components Metal Stamping Parts - Automotive Cross Member Part – Meiln Detail:

Brief Description: Seamless Welding Process

Part Name: Automotive Cross Member Part

Material Grade: Material Grade LAH420Y480T

Material Size: Material size is 2.20mm x 775mm x 215mm

Stage Process: 500T Progressive Blanking and 2000T Transfer with 5 stages

Cavity: Tool cavity is one part out

Press Machine: 630T Mechanical and 1200T Mechanical

Feeder Machine: Coil material for trial

Inspection Tool: Checking fixture, CMM

Lead Time: 3.5 months

Technical Key Point: the middle central area seamless welding

In order to meet the requirement of seamless welding for the central area, part surface, especially flatness must be in a high quality.

Seamless welding is commonly used in the automotive industry mostly known as piping and tubing, and seamless welding machine.

Here what we discussed is automotive child product welding, not steel pipes or tubes. For automotive product seamless welding, it requires high flatness of the welding surface, no clearance. Fit and match correctly with the opposite product is the target.

How to make seamless welding succeed?

For the product, the key point is trim line and surface flatness quality, with smooth surface, no hole deformed, no burrs and no dents, especially for notch areas.

In the die processes, flange mostly determined the surface quality. To control this important welding area, we have checked carefully. The first die off parts quality nearing 95%, however, surface not good enough for seamless welding. The forming steel coating and surface have been double reviewed and tested.

In the process of seamless welding, product deforming, twist and splitting might be occurred due to different material grade, thickness and shape.

Although the key point is metal product in high quality, while should pay attention to other factors.

Please contact with us about seamless welding, if you have query about process, quality control and improvement, we will share with you our opinions.

Product detail pictures:

Related Product Guide:

Good quality comes to start with; service is foremost; organization is cooperation" is our enterprise philosophy which is regularly observed and pursued by our firm for Factory Cheap Cnc Checking Fixture Components Metal Stamping Parts - Automotive Cross Member Part – Meiln , The product will supply to all over the world, such as: Hungary, Greece, Malaysia, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.